-

Search Products

- Support and Downloads

- Inquire Now

Ferrule couplings for food, beverage, and chemical equipment and facility piping (for Toyox hoses)

TOYOCONNECTOR TC3-F

- Model | TC3-F

- Material | Stainless steel

Features

-

Fluid accumulation prevention

-

Leak and disconnection prevention

-

Standardization of work

-

Hygienic

Related video

Download materials

Product features

-

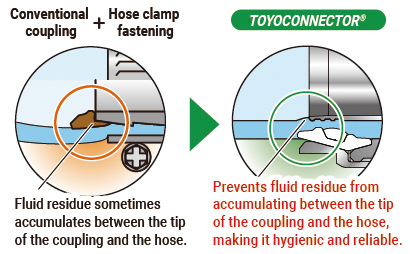

Fluid accumulation prevention

Hygienic design with a nipple shape that prevents fluid accumulation, making it ideal for food and beverage products.

Fluid accumulation prevention

Hygienic design with a nipple shape that prevents fluid accumulation, making it ideal for food and beverage products.

-

Leak and disconnection prevention

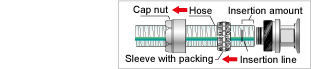

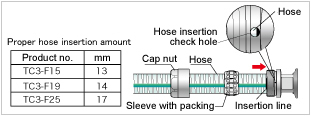

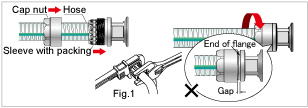

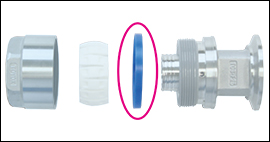

Attaches securely to the hose with a special sleeve construction, eliminating fluid leaks and hose disconnections.

Leak and disconnection prevention

Attaches securely to the hose with a special sleeve construction, eliminating fluid leaks and hose disconnections.

-

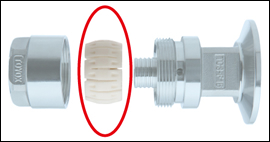

Standardization of work

The cap nut means no bothersome clamp position adjustments or torque control so work can be standardized.

Standardization of work

The cap nut means no bothersome clamp position adjustments or torque control so work can be standardized.

-

Hygienic

Rust-resistant and hygienic stainless-steel design (equivalent to SUS 316L, SUS 304).

Hygienic

Rust-resistant and hygienic stainless-steel design (equivalent to SUS 316L, SUS 304).

TOYOCONNECTOR TC3-F

Ferrule couplings for food, beverage, and chemical equipment and facility piping (for Toyox hoses)

- Hose side

- Cap nut

- Hose inner diameter (mm)

- 15, 19, 25

- Device side

- Ferrule

- Coupling specifications

- 1S

| Model No. | TC3-F | |

|---|---|---|

| Main material | ||

| Function | ||

| Fluid | Water (industrial use) Air Oil Food and beverage Chemicals and cosmetics Solvents and paints | |

| Legal compliance | RoHS 2 compliant | |

| Material details | Nipple | SCS16 (SUS316L equivalent) |

| Cap nut | SCS13 (SUS304 equivalent) | |

| Sleeve | Polyacetal | |

| Packing | Silicone rubber | |

| Resin ring | Polyacetal (color-coded models only) | |

Coupling specifications

| Model | Compatible hose inner diameter (mm) |

Coupling specifications | Dimensions (mm) | Weight (g) | No. of packaged items | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Width across flats | A | B | C | HEX | L | Φd1 | |||||

| TC3-F15-1S | 15 | 1S | 24 | 50.5 | 43.5 | 23 | 31 | 58.5 | 13 | 238 | 10 |

| TC3-F19-1S | 19 | 1S | 27 | 50.5 | 43.5 | 23 | 36 | 60.5 | 17 | 290 | 10 |

| TC3-F25-1S | 25 | 1S | 30 | 50.5 | 43.5 | 23 | 42 | 66 | 22.5 | 392 | 10 |

Precautions

*The TOYOCONNECTOR is designed as a genuine coupling for Toyox hoses. Toyox makes no guarantee that the TOYOCONNECTOR will function properly if connected to another manufacturer's hose.

-

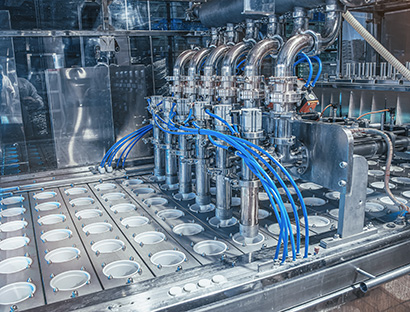

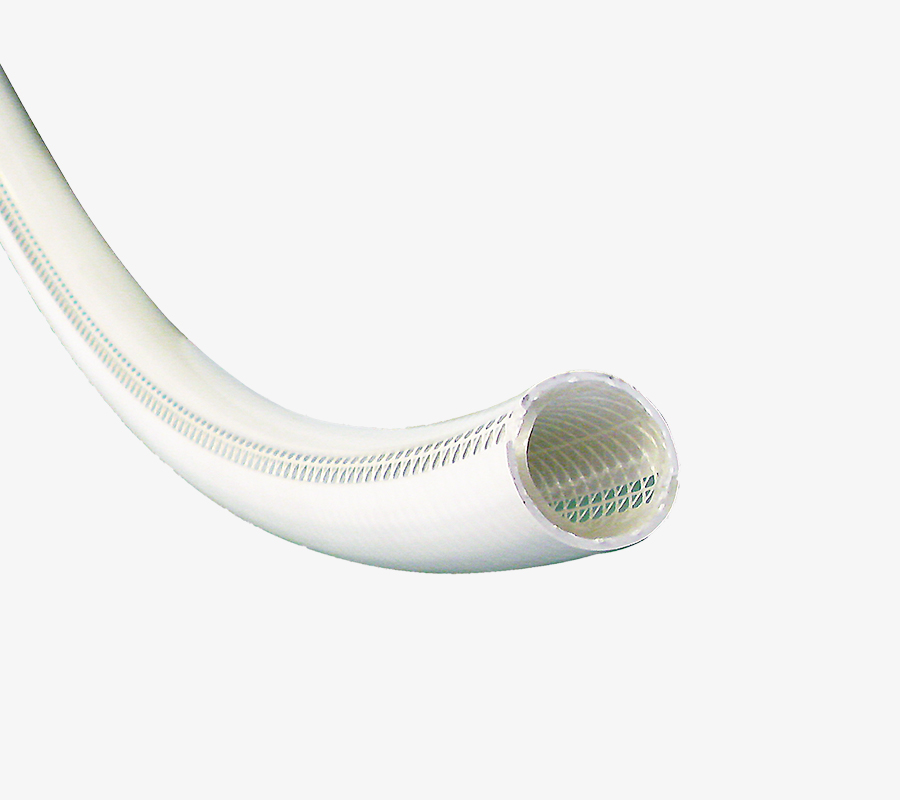

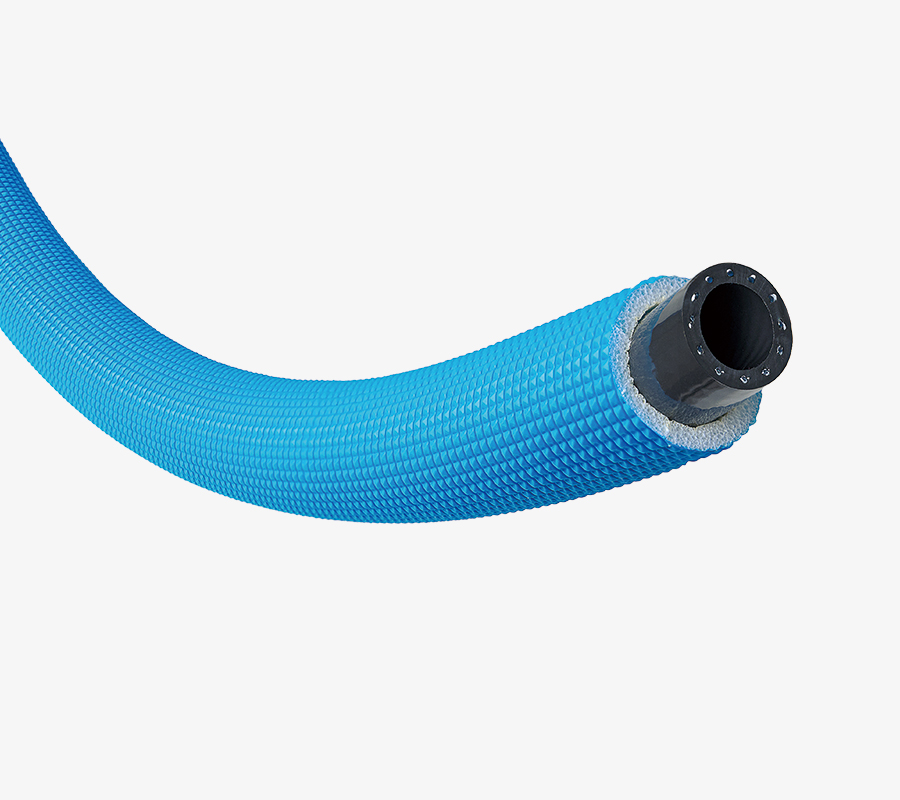

Food and beverage workplaces

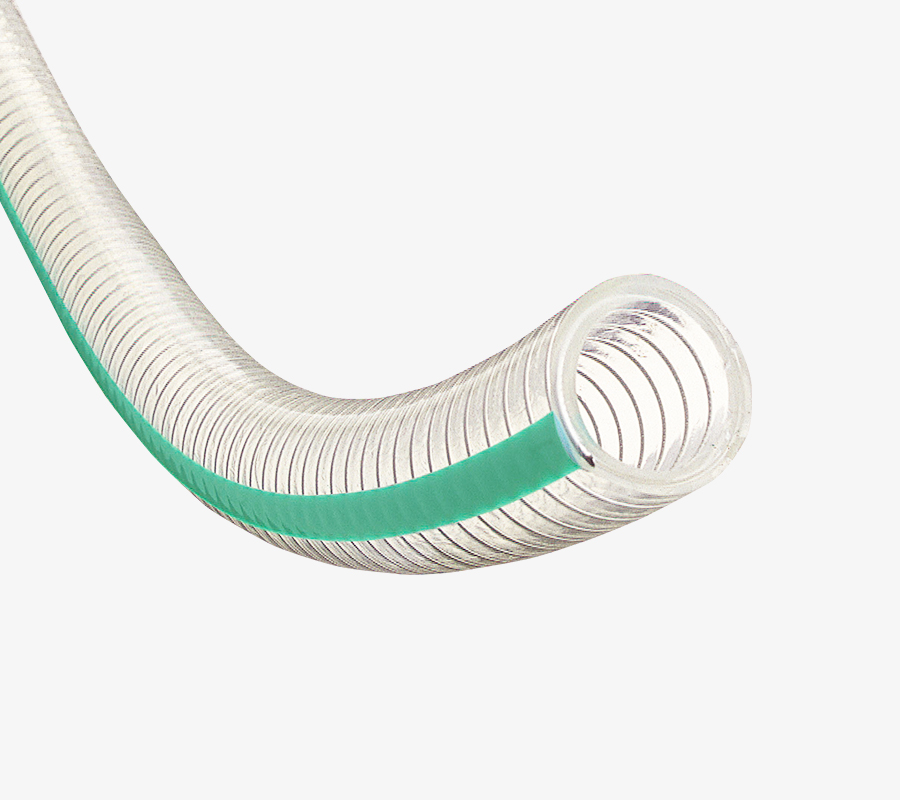

Hard steel wire in spring hoses causes rust issues

- Reduced production problems

- Sanitary measures

- Reduced product loss

-

Food and beverage workplaces

Cleaning alcohol makes the hoses stiff, causing outbreaking crack on the serface and leaks

- Improved workability

- Reduced maintenance

- Improved production efficiency

-

Food and beverage workplaces

Improving resistance to odors and fluid accumulation at couplings for increased production efficiency

- Foreign substance contamination measures

- Improved production efficiency

- Coloring and odor countermeasures

-

Food and beverage workplaces

Issues caused by clamps were eliminated, enabling stable production

- Reduced production problems

- Cost reduction

- Improved production efficiency

-

Pharmaceutical / Cosmetic / Chemical workplaces

Less odor transferred to hoses, less liquid pooling in couplings, and increased work productivity!

- Cost reduction

- Reduced maintenance

- Coloring and odor countermeasures

-

Food and beverage workplaces

Parts replaced to prevent hose disconnections and leaks from couplings, in order to help prevent work-related burn injuries

- Reduced production problems

- Enhanced safety

-

Food and beverage workplaces

I want to change hoses to meet the revised Food Sanitation Act, but oils & fats remain a problem

- Reduced time spent on work

- Foreign substance contamination measures

- Laws and regulations

-

Pharmaceutical / Cosmetic / Chemical workplaces

Switching to a reusable product reduced costs and ensured safety (preventing disconnections)

- Reduced production problems

- Reuse

- Cost reduction

-

Food and beverage workplaces

Liquid accumulation between barb fittings and hoses is a concern due to dairy components in flavorings

- Reduced production problems

- Foreign substance contamination measures

- Reduced product loss

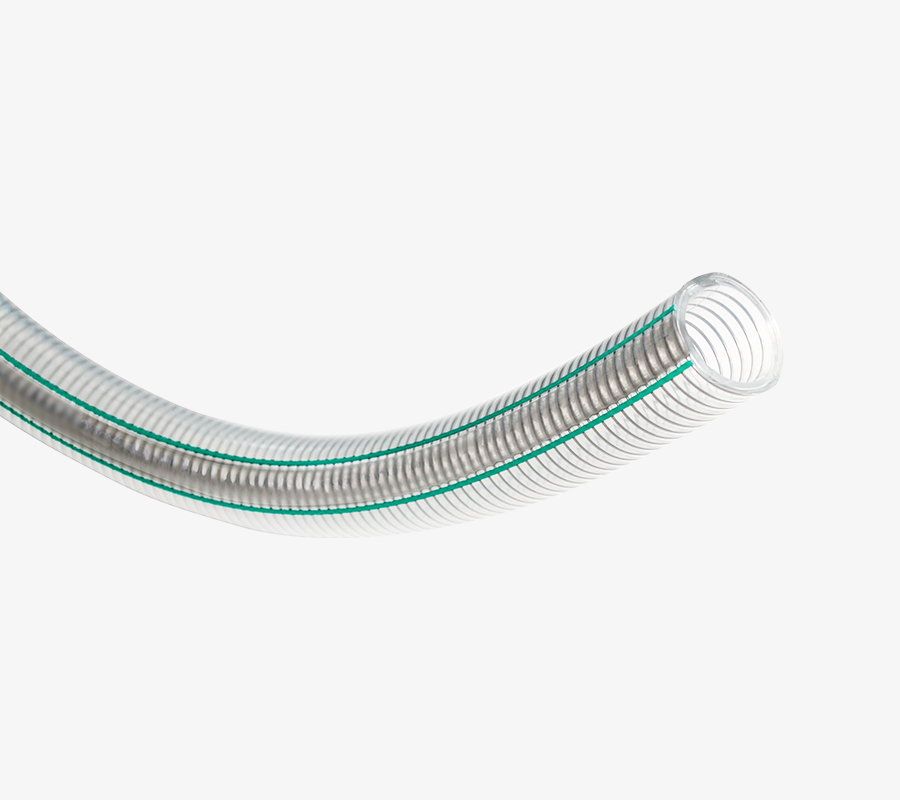

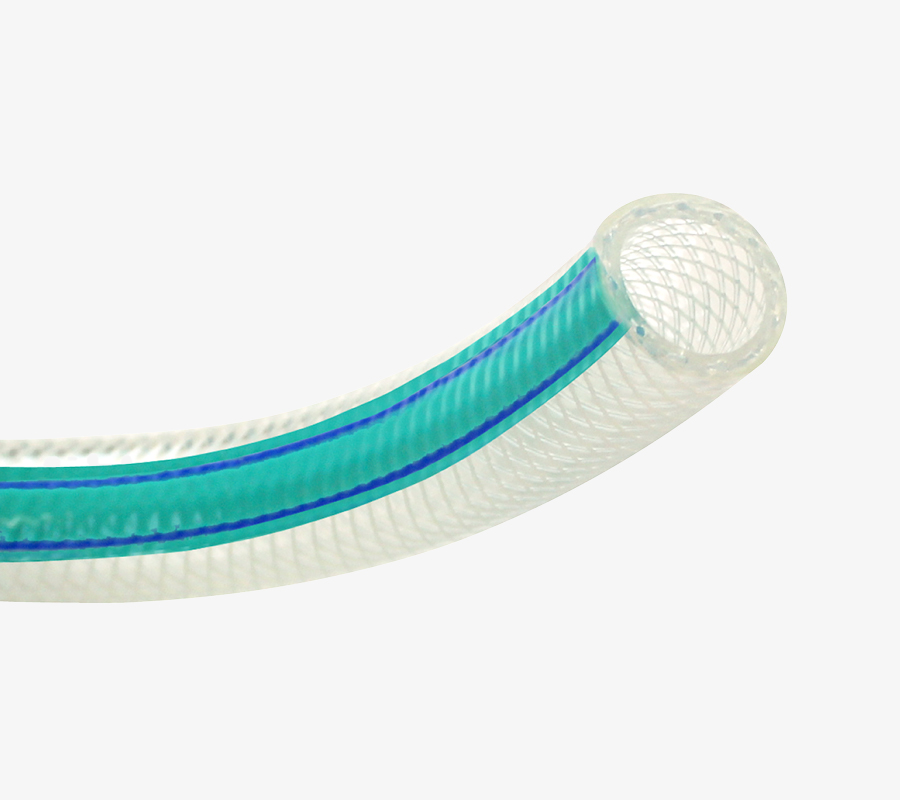

Compatible Hoses: 22

|

Hose name | ECORON HOSE | TOYOFUSSO HOSE | TOYOFUSSO-E HOSE | TOYOFUSSO-S HOSE | TOYOFUSSO SOFT HOSE | HYPER TOYORON HOSE | HYBRID TOYOFOODS HOSE | HYBRID TOYORON HOSE | SUPER TOYORON HOSE | TOYOBIO PRO HOSE | TOYOFOODS HOSE | TOYORING HOSE | TOYORING-F HOSE | TOYORON HOSE | TOYOSPRING HOSE | TOYOSIGNAL HOSE | FLAMEBLC HOSE | FLAMEBLC HYBRID UL HOSE | HYBRID TOYODROP HOSE | TOYOFUSSO SOFT−S HOSE | ECORON-S HOSE | TOYOFOODS-S HOSE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main material | Polyolefin resin | Tetrafluororesin | Tetrafluororesin | Tetrafluororesin | Tetrafluororesin | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Tetrafluororesin | Polyolefin resin | Soft PVC | |

| Operating temperature range | -5℃~60℃ | -20℃~80℃ | -20℃~80℃ | -20℃~80℃ | -5℃~70℃ | -5℃~70℃ | -5℃~70℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~70℃ | -5℃~60℃ | -5℃~70℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~70℃ | -5℃~60℃ | -5℃~70℃ | |

| Model No. | EC | FF | FFE | FFS | FFY | HPT | HTF | HTR | ST | TBP | TFB | TG | TGF | TR | TS | TSG | FB | FBH | HTD | FFYS | ECS | TFS | |

| Coupling model |

Compatible hose nominal inner diameter (mm)

Coupling specifications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TC3-F15-1S |

15

1S

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| TC3-F19-1S |

19

1S

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - |

| TC3-F25-1S |

25

1S

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Replacement Sleeve Set | Replacement Sleeve Set | Compatible TOYOCONNECTOR Part Number | Packing Unit |

|---|---|---|---|

| pc | |||

|

TC3-F15-RSS | TC3-F15 all types |

10 |

| TC3-F19-RSS | TC3-F19 all types |

10 | |

| TC3-F25-RSS | TC3-F25 all types |

10 |

* The replacement parts for the TC3-F are the same as for the TC3-CS.

- 材質 /

- Sleeve : Polyacetal

Packing : Silicone rubber

| Replacement Sleeve Set | Part Number | Compatible TOYOCONNECTOR Part Number | Packing Unit |

|---|---|---|---|

| pc | |||

|

TC3-F15-PO (BL / RD / YE / GR) |

TC3-F15-1S-(BL / RD / YE / GR) | 1 |

| TC3-F19-PO (BL / RD / YE / GR) |

TC3-F19-1S-(BL / RD / YE / GR) | 1 | |

| TC3-F25-PO (BL / RD / YE / GR) |

TC3-F25-1S-(BL / RD / YE / GR) | 1 |

Precaution: Contact with a fluid may result in discoloration, degradation or breakage of the plastic ring depending on the type of fluid. If an abnormality is found, replace with a new plastic ring.

- 材質 /

- Resin ring : Polyacetal

Attachment Tool

Use a wrench such as a regular adjustable or monkey wrench to finish tightening. Do not, however, use a pipe wrench as it will damage the nut portion.