Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Pharmaceutical / Cosmetic / Chemical workplaces

Improvement Case

Case studiesPharmaceutical / Cosmetic / Chemical workplaces

Pharmaceutical / Cosmetic / Chemical workplaces

Less odor transferred to hoses, less liquid pooling in couplings, and increased work productivity!

- Improvement by theme

-

Cost reduction

Reduced maintenance

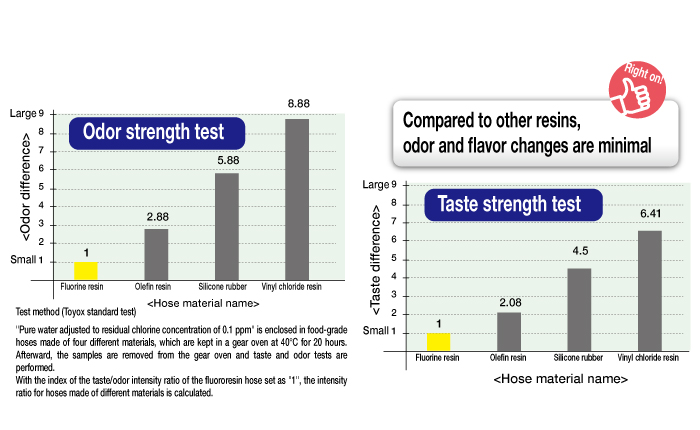

Coloring and odor countermeasures

- Fluid/Application

-

Chemicals and cosmetics

- Product name

-

TOYOFUSSO SOFT HOSE

/

TOYOCONNECTOR TC3-F

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ Silicone hose / Ferrule hose nipple / Hose clamp ]

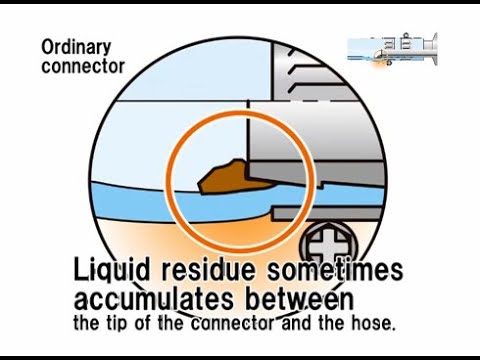

Silicone hoses fastened with hose clamps were being used to transfer products and clean with alcohol during cosmetics filling processes. However, these silicone hoses were being replaced once every six months, due to concerns about odors coming from them. There were also sanitary concerns due to liquid pooling, so employees had been disassembling and cleaning hoses every day. This created a lot of extra work.

After[ TOYOFUSSO SOFT HOSE / TOYOCONNECTOR TC3-F ]

The customer switched to TOYOFUSSO Soft Hoses (with non-adhesive with excellent water repellency) and nipple-shaped TOYOCONNECTORs (to help prevent liquid from pooling). This significantly reduced odor transfer, and also greatly reduced the amount of time required for cleaning. The customer confirmed that there was no bacteria left after cleaning, and was able to reduce hose replacement costs by 300,000 JPY per year.