-

Search Products

- Support and Downloads

- Inquire Now

Couplings for plant facility piping (for Toyox hoses)

TOYOCONNECTOR TC3-S

- Model | TC3-S

- Material | Stainless steel

Features

-

Leak and disconnection prevention

-

Energy-saving

-

Reduced time spent on piping work

-

Durability

Related video

Download materials

Product features

-

Leak and disconnection prevention

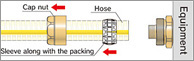

Hose insertion is easy and the cap nut tightens without gaps to prevent the hose from coming loose and leaking fluid.

Leak and disconnection prevention

Hose insertion is easy and the cap nut tightens without gaps to prevent the hose from coming loose and leaking fluid.

-

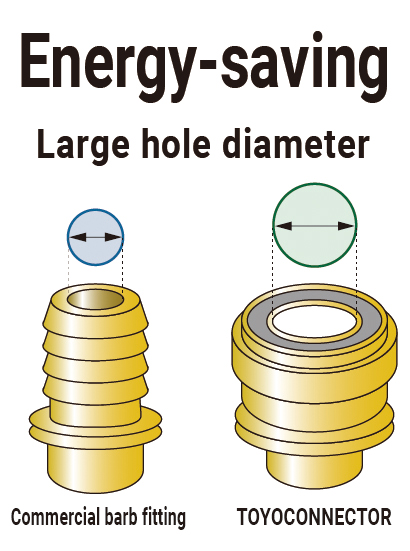

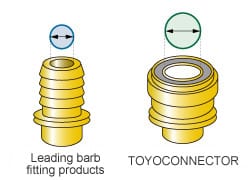

Energy-saving

Larger effective sectional area of the hose nozzle than barb fittings for reduced pressure loss and minimal power consumption.

Energy-saving

Larger effective sectional area of the hose nozzle than barb fittings for reduced pressure loss and minimal power consumption.

-

Reduced time spent on piping work

No need for cumbersome clamp alignment, torque control, or retightening. Enables installation to be performed uniformly.

Reduced time spent on piping work

No need for cumbersome clamp alignment, torque control, or retightening. Enables installation to be performed uniformly.

-

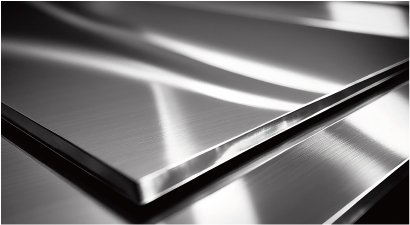

Durability

Made of rust-resistant SCS13 (equivalent to SUS 304) stainless steel, preventing the elution of steel materials.

Durability

Made of rust-resistant SCS13 (equivalent to SUS 304) stainless steel, preventing the elution of steel materials.

TOYOCONNECTOR TC3-S

Couplings for plant facility piping (for Toyox hoses)

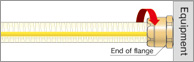

- Hose side

- Cap nut

- Hose inner diameter (mm)

- 9, 12, 15, 19, 25

- Device side

- Male thread

- Connection size

- R1/4, R3/8, R1/2, R3/4, R1

| Model No. | TC3-S | |

|---|---|---|

| Main material | ||

| Function | ||

| Fluid | Water (industrial use) Air Oil Chemicals and cosmetics Solvents and paints | |

| Legal compliance | RoHS 2 compliant | |

| Material details | Nipple | SCS13 (SUS304 equivalent) 9-R3/8, 12-R1/2, 15-R1/2, 19-R3/4, 25-R1 | AISI304F (SUS304 equivalent) 9-R1/4, 12-R3/8, 15-R3/8, 19-R1/2, 25-R3/4 | SUS304 15-R3/4, 19-R1 |

| Cap nut | SCS13 (SUS304 equivalent) | |

| Sleeve | Polyacetal | |

| Rubber seal | NBR | |

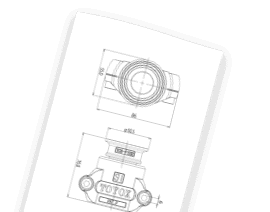

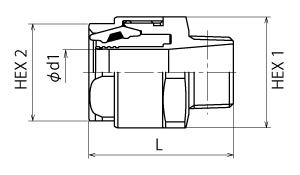

Coupling specifications

| Model | Compatible hose inner diameter (mm) |

Thread standard | Dimensions (mm) | Weight (g) | No. of packaged items | |||

|---|---|---|---|---|---|---|---|---|

| L | Φd1 | HEX1 | HEX2 | |||||

| TC3-S9-R1/4 | 9 | R1/4 | 43.0 | 7.0 | 29 | 24 | 100 | 20 |

| TC3-S9-R3/8 | R3/8 | 43.5 | 7.0 | 29 | 24 | 100 | 20 | |

| TC3-S12-R3/8 | 12 | R3/8 | 44.5 | 10.0 | 32 | 27 | 123 | 20 |

| TC3-S12-R1/2 | R1/2 | 48.0 | 10.0 | 32 | 27 | 130 | 20 | |

| TC3-S15-R3/8 | 15 | R3/8 | 44.5 | 11.5 | 36 | 31 | 157 | 20 |

| TC3-S15-R1/2 | R1/2 | 48.0 | 13.0 | 36 | 31 | 145 | 20 | |

| TC3-S15-R3/4 | R3/4 | 49.5 | 13.0 | 36 | 31 | 218 | 20 | |

| TC3-S19-R1/2 | 19 | R1/2 | 52.0 | 15.0 | 41 | 36 | 232 | 10 |

| TC3-S19-R3/4 | R3/4 | 53.5 | 16.5 | 41 | 36 | 220 | 10 | |

| TC3-S19-R1 | R1 | 56.5 | 16.5 | 41 | 36 | 225 | 10 | |

| TC3-S25-R3/4 | 25 | R3/4 | 56.0 | 20.5 | 49 | 42 | 338 | 10 |

| TC3-S25-R1 | R1 | 59.0 | 22.5 | 49 | 42 | 320 | 10 | |

Related links

Precautions

*Because of the presence of threads,This is not appropriate for sanitary hoses (such as used for foods). Use for foods may result in safety issues in the product.

-

Machinery manufacturing workplaces

Stiff hoses have to be softened with hot water before use

- Reduced time spent on work

- Improved production efficiency

-

Semiconductor and precision instrument workplaces

Damage avoided by preventing incidents caused by hose coupling leaks and disconnections

- Reduced production problems

- Cost reduction

-

Food and beverage workplaces

Reduced time spent cleaning hoses, and increased both work efficiency and productivity

- Reduced time spent on work

- Foreign substance contamination measures

- Improved production efficiency

-

Machinery manufacturing workplaces

Eliminating oil leaks due to steel piping cracks caused by vibration, and making site operations easier

- Reduced production problems

- Piping in tight spaces

- Noise countermeasures

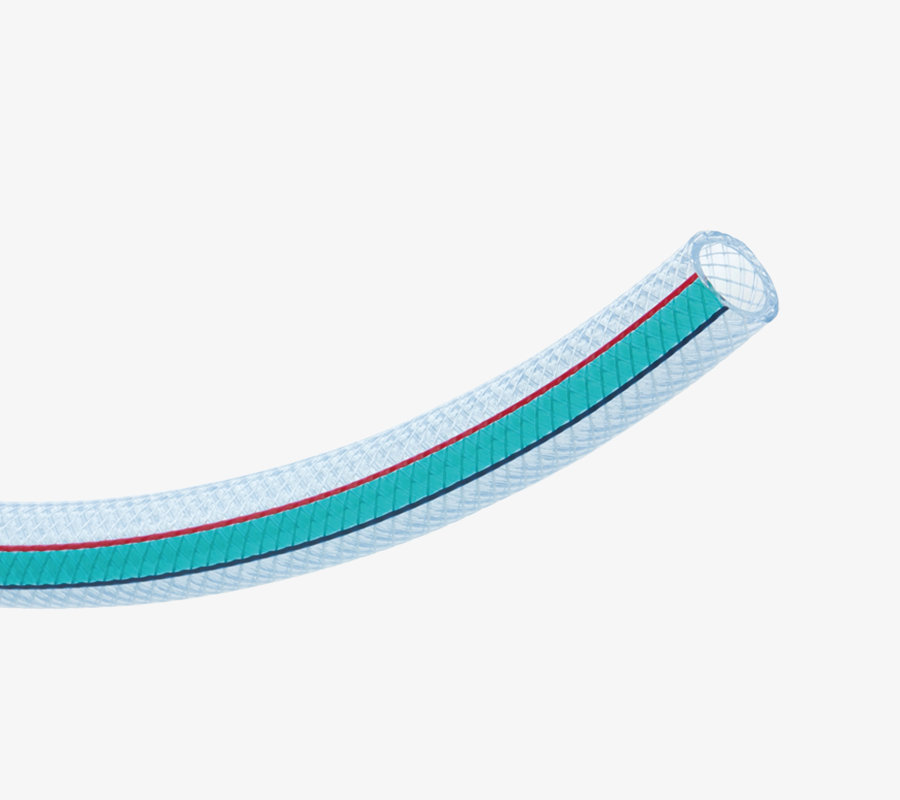

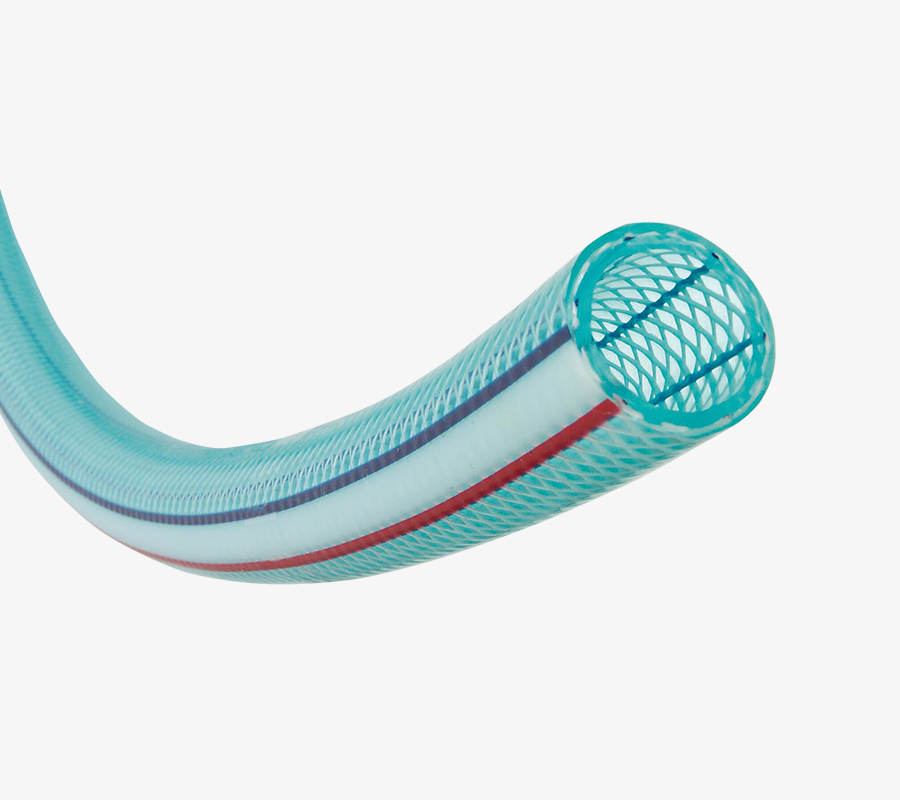

Compatible Hoses: 22

|

Hose name | ECORON HOSE | TOYOFUSSO HOSE | HYPER TOYORON HOSE | HYBRID TOYORON HOSE | SUPER TOYORON HOSE | TOYOFOODS HOSE | TOYORING HOSE | TOYORON HOSE | TOYOSPRING HOSE | TOYOSIGNAL HOSE | FLAMEBLC HOSE | HYBRID TOYODROP HOSE | TOYOFUSSO-E HOSE | TOYOFUSSO SOFT HOSE | FLAMEBLC HYBRID UL HOSE | TOYOFUSSO-S HOSE | HYBRID TOYOFOODS HOSE | TOYOBIO PRO HOSE | TOYORING-F HOSE | TOYOFUSSO SOFT−S HOSE | ECORON-S HOSE | TOYOFOODS-S HOSE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main material | Polyolefin resin | Tetrafluororesin | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Soft PVC | Tetrafluororesin | Tetrafluororesin | Soft PVC | Tetrafluororesin | Soft PVC | Soft PVC | Soft PVC | Tetrafluororesin | Polyolefin resin | Soft PVC | |

| Operating temperature range | -5℃~60℃ | -20℃~80℃ | -5℃~70℃ | -5℃~60℃ | -5℃~60℃ | -5℃~70℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -5℃~60℃ | -20℃~80℃ | -5℃~70℃ | -5℃~60℃ | -20℃~80℃ | -5℃~70℃ | -5℃~60℃ | -5℃~70℃ | -5℃~70℃ | -5℃~60℃ | -5℃~70℃ | |

| Model No. | EC | FF | HPT | HTR | ST | TFB | TG | TR | TS | TSG | FB | HTD | FFE | FFY | FBH | FFS | HTF | TBP | TGF | FFYS | ECS | TFS | |

| Coupling model |

Compatible hose nominal inner diameter (mm)

Coupling specifications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TC3-S9-R1/4 |

9

R1/4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - | - | - | - | - | - | - | - |

| TC3-S9-R3/8 |

9

R3/8

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - | - | - | - | - | - | - | - |

| TC3-S12-R3/8 |

12

R3/8

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - | - | - | - | - |

| TC3-S12-R1/2 |

12

R1/2

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - | - | - | - | - |

| TC3-S15-R3/8 |

15

R3/8

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| TC3-S15-R1/2 |

15

R1/2

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| TC3-S15-R3/4 |

15

R3/4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| TC3-S19-R1/2 |

19

R1/2

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ | ◯ | - | - |

| TC3-S19-R3/4 |

19

R3/4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ | ◯ | - | - |

| TC3-S19-R1 |

19

R1

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ | ◯ | - | - |

| TC3-S25-R3/4 |

25

R3/4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TC3-S25-R1 |

25

R1

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Replacement Sleeve Set | Part Number | Compatible TOYOCONNECTOR Part Number | Packing Unit |

|---|---|---|---|

| pc | |||

|

TC3-9-RSS | TC3-S9-R3/8,TC3-S9-R1/4 | 20 |

| TC3-12-RSS | TC3-S12-R1/2,TC3-S12-R3/8 | 20 | |

| TC3-15-RSS | TC3-S15-R1/2,TC3-S15-R3/8 | 20 | |

| TC3-19-RSS | TC3-S19-R3/4,TC3-S19-R1/2 | 10 | |

| TC3-25-RSS | TC3-S25-R1,TC3-S25-R3/4 | 10 |

- 材質 /

- Sleeve : Polyacetal resin

Rubber seal : NBR

(Same for the TC3-B and TC3-S)

Attachment Tool

Use a wrench such as a regular adjustable or monkey wrench to finish tightening. Do not, however, use a pipe wrench as it will damage the nut portion.