-

Search Products

- Support and Downloads

- Inquire Now

heat-resistant, wear-resistant, anti-static

TOYOTOP-E100°C HOSE

Model | TPE100C

Features

-

Prevents hose kinking or collapsing caused by high temperatures

-

Prevents perforation due to wear and foreign substance contamination

-

Prevents static-related problems

-

Usable for vacuum applications

Related video

Download materials

Product features

-

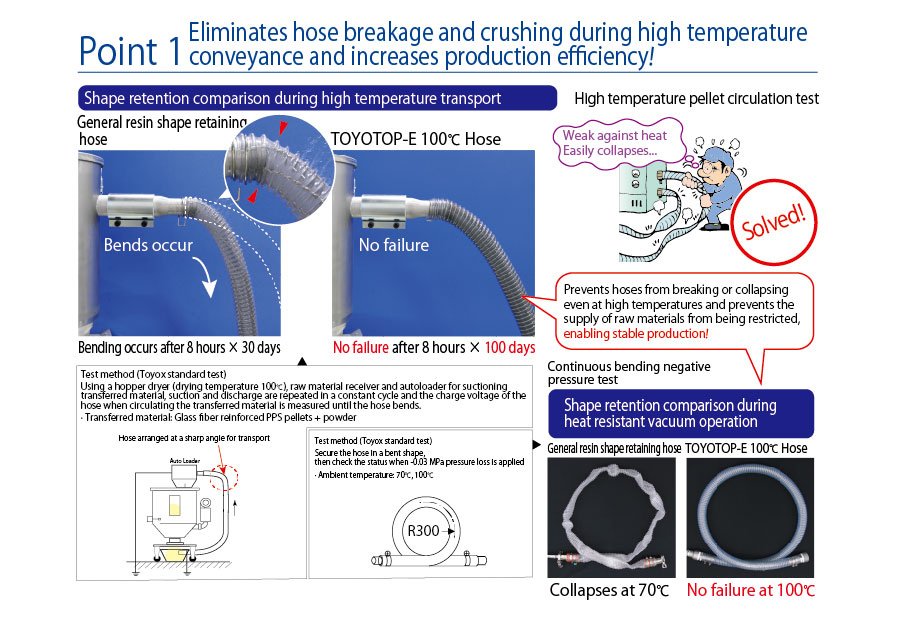

Prevents hose kinking or collapsing caused by high temperatures

With heat resistance performance up to 100°C, these hoses can be used for conveying hot plastic pellets or suction and pressure feeds of engineering-plastic type powder and granular materials after predrying. Reinforced metal wire with excellent shape retention prevents hose kinking or collapse even at high temperatures, allowing for stable conveyance.

Prevents hose kinking or collapsing caused by high temperatures

With heat resistance performance up to 100°C, these hoses can be used for conveying hot plastic pellets or suction and pressure feeds of engineering-plastic type powder and granular materials after predrying. Reinforced metal wire with excellent shape retention prevents hose kinking or collapse even at high temperatures, allowing for stable conveyance.

-

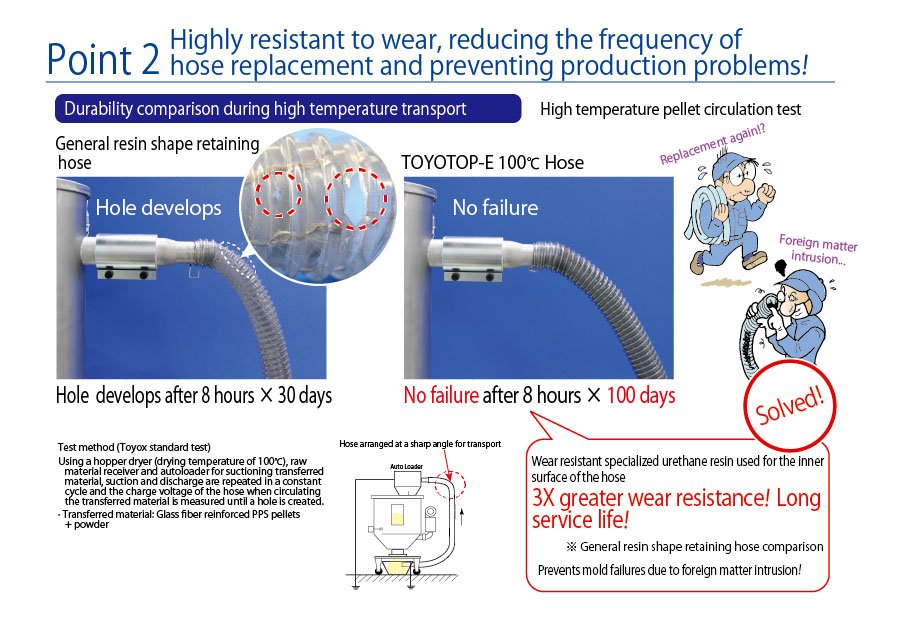

Prevents perforation due to wear and foreign substance contamination

Abrasion-resistant specialized urethane resin is used for the inner surface of the hose. Three times more durable than conventional products * Toyox product comparison

Prevents perforation due to wear and foreign substance contamination

Abrasion-resistant specialized urethane resin is used for the inner surface of the hose. Three times more durable than conventional products * Toyox product comparison

-

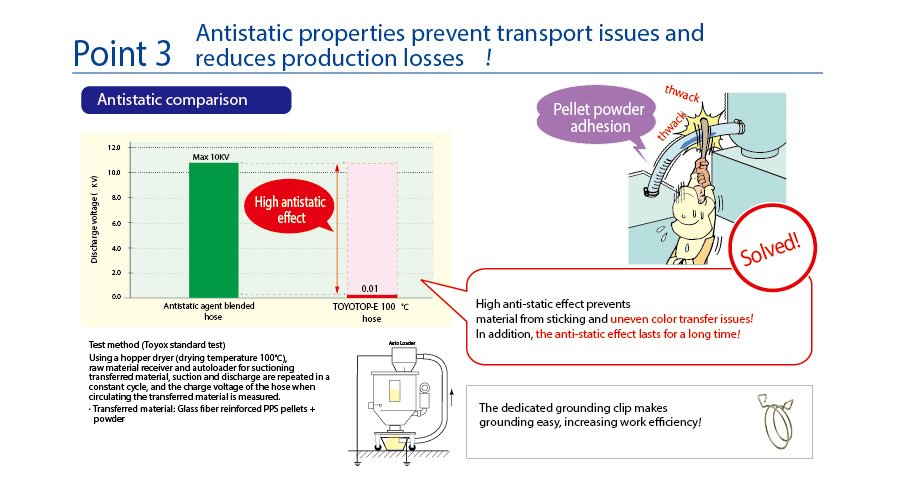

Prevents static-related problems

The structure integrates a metal wire that accumulates static electricity and an antistatic band with a grounding function to provide excellent antistatic effects. Prevents conveyance issues such as uneven color due to raw material adhesion

Prevents static-related problems

The structure integrates a metal wire that accumulates static electricity and an antistatic band with a grounding function to provide excellent antistatic effects. Prevents conveyance issues such as uneven color due to raw material adhesion

-

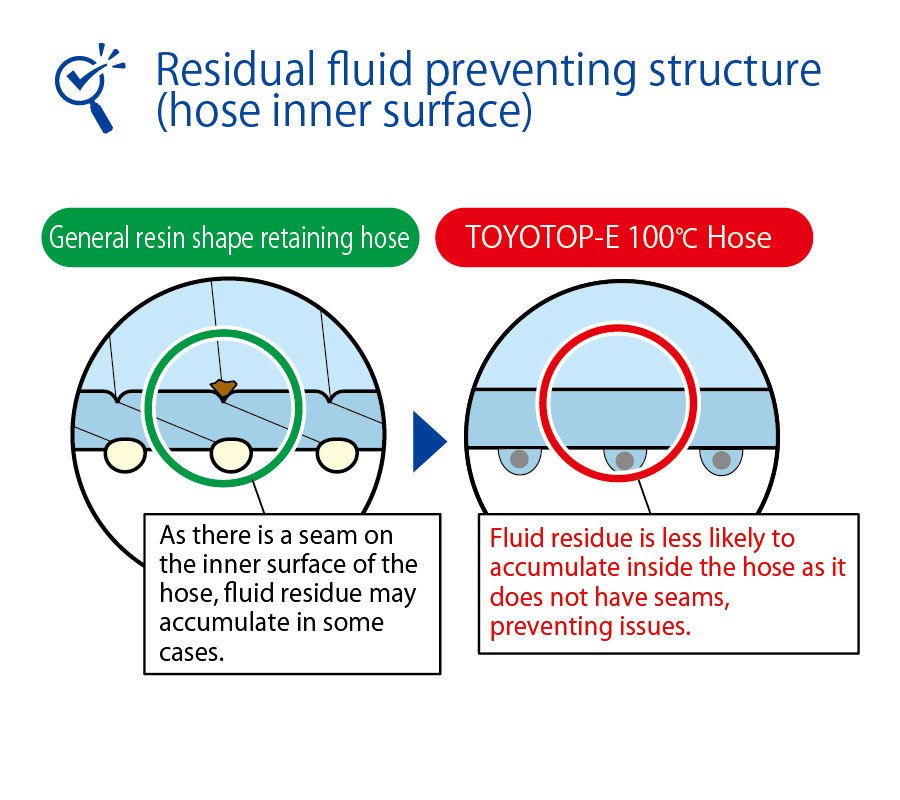

Preventing production trouble due to foreign substance contamination

Plastic powder is less likely to accumulate inside the hose as it is smooth and seamless. Prevents grounding thread (lead wire) contamination, as grounding threads (lead wires) are not used on the hose exterior. * Toyox product comparison

Preventing production trouble due to foreign substance contamination

Plastic powder is less likely to accumulate inside the hose as it is smooth and seamless. Prevents grounding thread (lead wire) contamination, as grounding threads (lead wires) are not used on the hose exterior. * Toyox product comparison

TOYOTOP-E100°C HOSE

heat-resistant, wear-resistant, anti-static

| Application | Engineering plastic type powder and granular materials (for high-temperature transport in drying equipment, etc.) | |

|---|---|---|

| Fluid | ||

| Function |

Positive pressure (pressure feed) Negative pressure (vacuum) High-pressure-resistant Heat-resistant Cold-resistant Transparent Flexible Kinking/collapse prevention Oil-resistant (animal/vegetable oil) Oil-resistant (mineral oil) Chemical-resistant Low odor Low elution Non-adhesive Antistatic Dew condensation prevention Abrasion-resistant Flame retardant Plasticizer-free Disposal sorting not required |

|

| Regulatory | RoHS 2 compliant | |

| Specification | Main material | Special polyurethane resin |

| Reinforcing material | Hard steel wire | |

| Inner diameter | 32mm~76.2mm | |

| Operating temperature range | -5℃~100℃ | |

| Other | ||

Specifications table by size Operating temperature range -5℃ 〜 100℃

| Model | Inner diameter × Outer diameter (mm) | Operating pressure (MPa) | Standard weight (kg/roll) | Standard length (m) | Minimum bending radius (mm) | |

|---|---|---|---|---|---|---|

| 50°C | 100°C | |||||

| TPE100C-25 | 25.0 × 35.7 | -0.1~0.2 | -0.03~0.1 | 10.2 | 20 | 200 |

| TPE100C-32 | 32.0 × 44.6 | -0.1~0.2 | -0.03~0.1 | 15.1 | 20 | 260 |

| TPE100C-38 | 38.0 × 50.6 | -0.1~0.2 | -0.03~0.1 | 17.6 | 20 | 300 |

| TPE100C-50 | 50.8 × 64.5 | -0.1~0.2 | -0.03~0.1 | 26.1 | 20 | 400 |

| TPE100C-63 | 63.5 × 80.7 | -0.05~0.1 | -0.03~0.05 | 36.7 | 20 | 500 |

| TPE100C-75 | 76.2 × 93.6 | -0.05~0.1 | -0.03~0.05 | 45.3 | 20 | 600 |

Packing: film packing Coloring: natural transparent

*-0.1 MPa is an approximate value. The product may not be used for some applications. See "Vacuum Pressure Reference Region".

Grounding clip (TFE/TPE100C)

| Part Number | Applicable hose | Packing unit (pc) | |

|---|---|---|---|

* This is not a hose clamp. |

TFEC-32 | TPE100C-32 | 10 |

| TFEC-38 | TPE100C-38 | ||

| TFEC-50 | TPE100C-50 | ||

| TFEC-63 | TPE100C-63 | 50 | |

| TFEC-75 | TPE100C-75 |

Click here for attachment instructions.

Related links

Precautions

* Do not use with fluids other than plastic powder and granular materials

* For efficient long-term anti-static effects, use the dedicated grounding clip

* After attaching the clip, check the continuity with a tester or similar device that has a measurement range of at least ×10K.

-

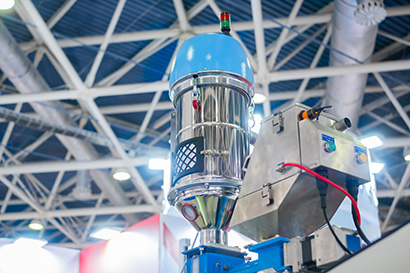

Factory equipment piping

Reduced hose degradation and improved production by increasing heat resistance, and increased efficiency by reducing how frequently parts need to be replaced

- Improved workability

- Reduced maintenance

- Improved production efficiency

-

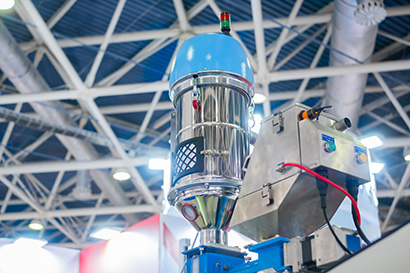

Plastic molding workplaces

Heat leads to hose collapse, preventing stable supply of raw materials

- Reduced production problems

- Foreign substance contamination measures

- Antistatic measures

-

Plastic molding workplaces

The improved anti-static design shortens cleaning times for greater work efficiency

- Reduced time spent on work

- Reduced production problems

- Antistatic measures

-

Plastic molding workplaces

Friction opens up holes in the hose, preventing stable supply of raw materials

- Reduced production problems

- Improved production efficiency

- Antistatic measures

-

Plastic molding workplaces

Improved wear resistance prevents holes from forming and foreign matter from entering

- Reduced time spent on work

- Reduced production problems

- Reduced product loss

-

Plastic molding workplaces

Hose interior material wears away, causing holes and requiring frequent hose replacement

- Reduced maintenance

- Foreign substance contamination measures

- Improved production efficiency

-

Factory equipment piping

Improved wear resistance prevents holes from forming and foreign matter from entering

- Reduced maintenance

- Foreign substance contamination measures

- Reduced product loss

Compatible KAMLOK

| Hose details | Hose connection | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening |

|---|---|---|---|---|---|---|---|---|---|---|

| Coupling specifications | Coupler | Coupler | Coupler | Coupler | Coupler | Coupler | Adapter | Adapter | Adapter | |

| Main material |

Aluminum alloy

|

Resin (PP)

|

Stainless steel

|

Aluminum alloy

|

Resin (PP)

|

Stainless steel

|

Aluminum alloy

|

Resin (PP)

|

Stainless steel

|

|

| Model No. | 633-C-AL | 633-C-PP | 633-C-SST | 633-CL-AL | 633-CL-PP | 633-CL-SST | 633-E-AL | 633-E-PP | 633-E-SST | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

|

|

|

| TPE100C-25 |

25.0

35.7

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TPE100C-32 |

32.0

44.6

|

◯ | - | ◯ | ◯ | - | ◯ | ◯ | - | ◯ |

| TPE100C-38 |

38.0

50.6

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TPE100C-50 |

50.8

64.5

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TPE100C-63 |

63.5

80.7

|

◯ | - | ◯ | ◯ | - | ◯ | ◯ | - | ◯ |

| TPE100C-75 |

76.2

93.6

|

◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | ◯ |