Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Factory equipment piping

Improvement Case

Case studiesFactory equipment piping

Factory equipment piping

Reduced hose degradation and improved production by increasing heat resistance, and increased efficiency by reducing how frequently parts need to be replaced

- Improvement by theme

-

Improved workability

Reduced maintenance

Improved production efficiency

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

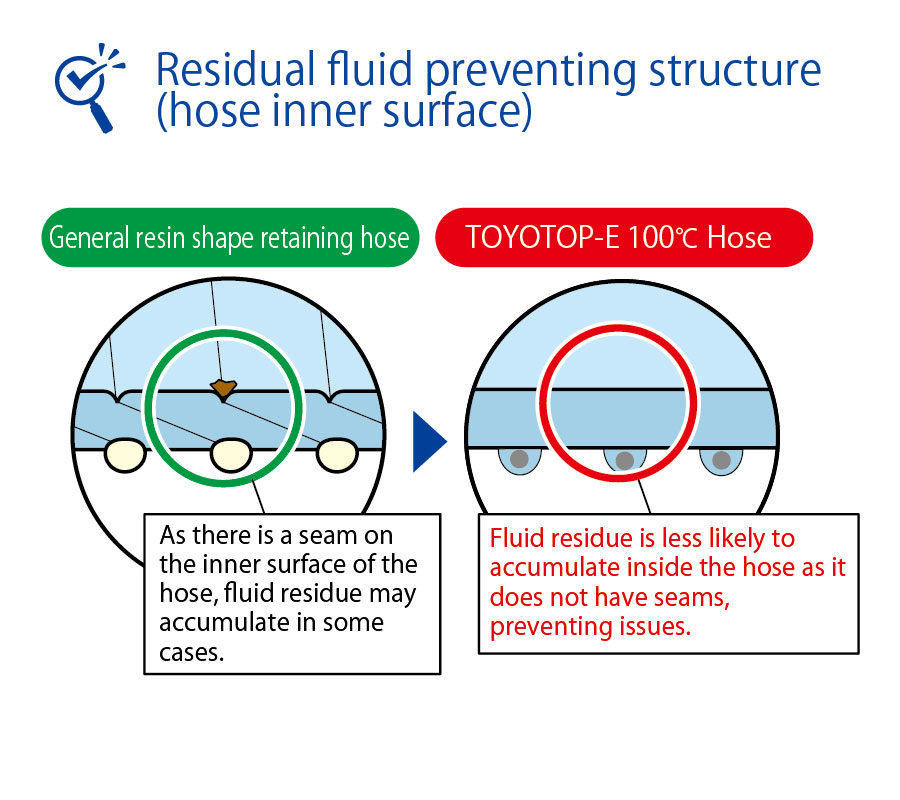

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Suction hose ]

The customer had been using a suction hose to transport plastic pellets for parts at an automotive parts plant. However, the temperature would rise to around 80°C during use, even though the hose had a heat resistance of only 50 to 60°C. The customer was suspicious of the ability of the hose to resist that much heat. This actually had caused the hose to degrade rapidly, and it often had to be replaced, reducing efficiency. Something had to be done.

After[ TOYOTOP-E100°C HOSE ]

The customer decided to use TOYOTOP-E 100°C Hose instead, which has a heat resistance of 100°C and would neither bend nor collapse near the coupling due to heat. The customer has had no heat-related issues since then and is able to produce products with peace of mind. They also plan to replace other piping as well.