Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

Plastic molding workplaces

Hose interior material wears away, causing holes and requiring frequent hose replacement

- Improvement by theme

-

Reduced maintenance

Foreign substance contamination measures

Improved production efficiency

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Plastic shape-retaining hose ]

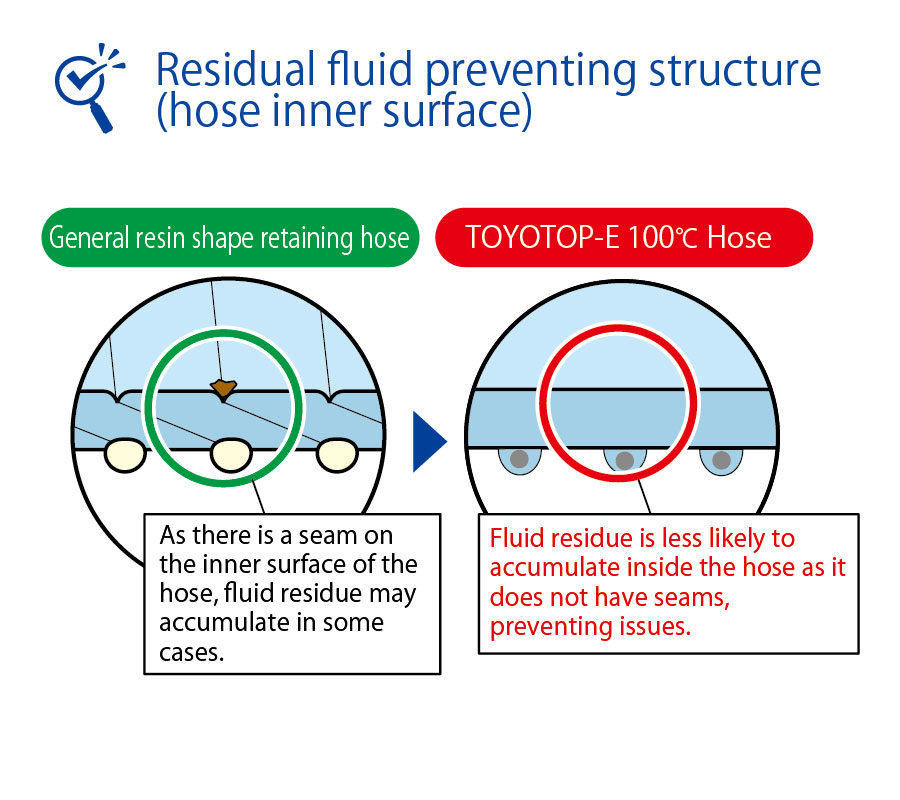

The interior material of the resin pellet transfer hose tended to wear away, leading to holes and requiring frequent hose replacement. The worn material contaminated the product as well, leading to product loss and reducing the yield.

After[ TOYOTOP-E100°C HOSE ]

Changing to TOYOTOP-E-100°C, with a wear-resistance function, enabled significant improvement of the wear on the hose interior, reducing the frequency of hose replacement. The product contamination with hose material was also ameliorated, enabling countermeasures for the low yield and leading to improved productivity.