Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Factory equipment piping

Improvement Case

Case studiesFactory equipment piping

Factory equipment piping

Improved wear resistance prevents holes from forming and foreign matter from entering

- Improvement by theme

-

Reduced maintenance

Foreign substance contamination measures

Reduced product loss

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Suction hose ]

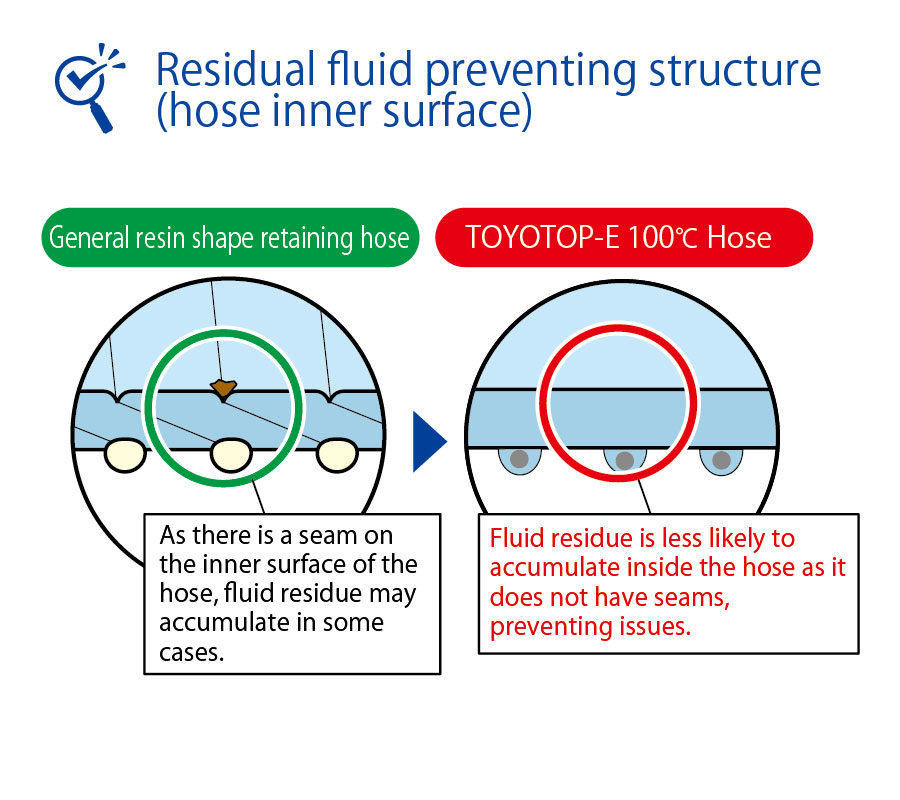

The customer had been using a suction hose to transport resin pellets to a molding machine hopper. However, after less than a year of use, deterioration due to wear caused holes to appear in the hose, from which debris entered, contaminating products with foreign matter and leading to defects.

After[ TOYOTOP-E100°C HOSE ]

The customer confirmed the performance difference in a TOYOTOP-E 100°C Hose wear resistance comparison video and put it to use for three months' monitoring. They found that use was possible without any problems with regard to wear resistance and flexibility, enabling secure production, so they decided to switch other lines as well. Compared to the conventional product, there was no product loss or trouble with replacement, leading to worksite improvements and pleasing the customer.