-

Search Products

- Support and Downloads

- Inquire Now

Multipurpose

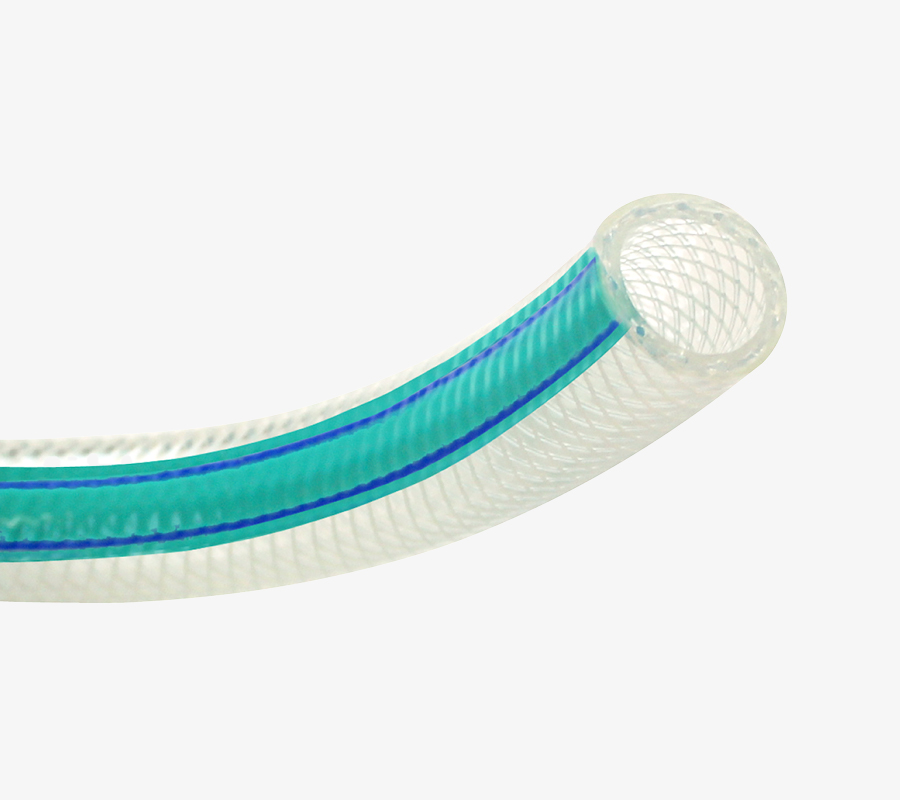

HYBRID TOYORON HOSE

Model | HTR

Features

-

Energy-saving

-

With a small bending radius useful for piping in tight spaces

-

Enables fluid conditions to be checked easily

Related video

Download materials

Product features

-

Energy-saving

Good shape retention for a braided hose minimizes pressure loss and provides energy savings. Resistant to kinking and collapsing, fluids are not stopped during conveyance, preventing production problems.

Energy-saving

Good shape retention for a braided hose minimizes pressure loss and provides energy savings. Resistant to kinking and collapsing, fluids are not stopped during conveyance, preventing production problems.

-

With a small bending radius useful for piping in tight spaces

Does not easily kink or collapse, so it can be used for piping in narrow spaces

With a small bending radius useful for piping in tight spaces

Does not easily kink or collapse, so it can be used for piping in narrow spaces

-

Enables fluid conditions to be checked easily

Highly transparent, allowing the fluid flowing through to be easily checked for greater peace of mind

Click here to check the transparency of the hose with a video

Enables fluid conditions to be checked easily

Highly transparent, allowing the fluid flowing through to be easily checked for greater peace of mind

Click here to check the transparency of the hose with a video

-

Resistant to hardening

Inner surface has excellent oil resistance and durability increased

Resistant to hardening

Inner surface has excellent oil resistance and durability increased

HYBRID TOYORON HOSE

Multipurpose

| Application | For factory equipment hoses and various equipment | |

|---|---|---|

| Fluid | ||

| Function |

Positive pressure (pressure feed) Negative pressure (vacuum) High-pressure-resistant Heat-resistant Cold-resistant Transparent Flexible Kinking/collapse prevention Oil-resistant (animal/vegetable oil) Oil-resistant (mineral oil) Chemical-resistant Low odor Low elution Non-adhesive Antistatic Dew condensation prevention Abrasion-resistant Flame retardant Plasticizer-free Disposal sorting not required |

|

| Regulatory | RoHS 2 compliant | |

| Specification | Main material | Soft PVC |

| Reinforcing material | Specialized PET resin / Polyester thread | |

| Inner diameter | 9mm~25mm | |

| Operating temperature range | -5℃~60℃ | |

| Other | ||

Specifications table by size Operating temperature range -5℃ 〜 60℃

| Model | Inner diameter × Outer diameter (mm) | Operating pressure (MPa) | Standard weight (kg/roll) | Standard length (m) | Minimum bending radius (mm) | |

|---|---|---|---|---|---|---|

| 23°C | 60°C | |||||

| HTR-9 | 9 × 15 | 0~1.5 | 0~1.0 | 15 | 100 | 40 |

| HTR-12 | 12 × 18 | 0~1.2 | 0~0.8 | 19 | 100 | 50 |

| HTR-15 | 15 × 22 | 0~1.0 | 0~0.8 | 25 | 100 | 70 |

| HTR-19 | 19 × 26 | 0~1.0 | 0~0.6 | 16 | 50 | 90 |

| HTR-25 | 25 × 33 | 0~1.0 | 0~0.6 | 24 | 50 | 120 |

Packing: Bobbin style Coloring: Blue transparent with image line

Related links

-

Factory equipment piping

Improving productivity by eliminating hose collapse and water leaks from couplings

- Reduced time spent on work

- Reduced production problems

- Piping in tight spaces

-

Machinery manufacturing workplaces

Eliminating oil leaks due to steel piping cracks caused by vibration, and making site operations easier

- Reduced production problems

- Piping in tight spaces

- Noise countermeasures

Compatible Couplings

| Hose details | Hose connection | Cap nut | Cap nut | Cap nut | Cap nut | Cap nut | Cap nut | Cap nut | Cap nut | Cap nut |

|---|---|---|---|---|---|---|---|---|---|---|

| Coupling specifications | Male thread | Male thread | Male thread | Male thread | Male thread | Male thread | Ferrule | Male thread | Coupler | |

| Main material |

Brass

|

Brass

|

Brass + resin

|

Resin (PPSU)

|

Stainless steel

|

Stainless steel

|

Stainless steel

|

Resin (PP)

|

Stainless steel

|

|

| Model No. | TC2-B | TC3-B | TC3-PB | TC3-PC | TC3-S | TC2-S | TC3-F | TC2-P | TC3-CS | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

|

|

|

| HTR-9 |

9

15

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| HTR-12 |

12

18

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| HTR-15 |

15

22

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - |

| HTR-19 |

19

26

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| HTR-25 |

25

33

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

Compatible KAMLOK

| Hose details | Hose connection | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Cap nut | Hose clamp tightening |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling specifications | Coupler | Coupler | Coupler | Coupler | Coupler | Adapter | Adapter | Adapter | Coupler | Coupler | |

| Main material |

Aluminum alloy

|

Resin (PP)

|

Stainless steel

|

Aluminum alloy

|

Stainless steel

|

Resin (PP)

|

Stainless steel

|

Aluminum alloy

|

Stainless steel

|

Resin (PP)

|

|

| Model No. | 633-C-AL | 633-C-PP | 633-C-SST | 633-CL-AL | 633-CL-SST | 633-E-PP | 633-E-SST | 633-E-AL | TC3-CS | 633-CL-PP | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

|

|

|

|

| HTR-9 |

9

15

|

- | - | - | - | - | - | - | - | - | - |

| HTR-12 |

12

18

|

- | - | - | - | - | - | - | - | - | - |

| HTR-15 |

15

22

|

- | - | - | - | - | - | - | - | - | - |

| HTR-19 |

19

26

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - |

| HTR-25 |

25

33

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |