Improvement Case

Case studies

IMPROVEMENT CASE

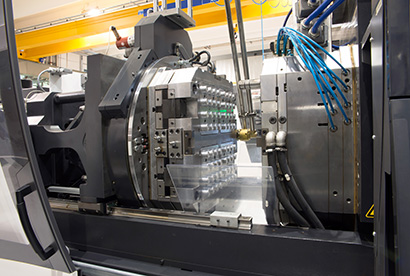

Plastic molding workplaces

View all-

Eliminating leakage problems, and making piping work easier and faster

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Cost reduction

-

Hose interior material wears away, causing holes and requiring frequent hose replacement

Improvement by theme

- Reduced maintenance

- Foreign substance contamination measures

- Improved production efficiency

-

Improved wear resistance prevents holes from forming and foreign matter from entering

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Reduced product loss

-

Friction opens up holes in the hose, preventing stable supply of raw materials

Improvement by theme

- Reduced production problems

- Improved production efficiency

- Antistatic measures

Pharmaceutical / Cosmetic / Chemical workplaces

View all-

Static electricity causes powder to stick to the hose, reducing production efficiency

Improvement by theme

- Enhanced safety

- Improved production efficiency

- Antistatic measures

-

Switching to a reusable product reduced costs and ensured safety (preventing disconnections)

Improvement by theme

- Reduced production problems

- Reuse

- Cost reduction

-

Replacement work is difficult due to the use of dedicated hoses for each product due to concerns about smell transfer

Improvement by theme

- Improved workability

- Reduced time spent on work

- Coloring and odor countermeasures

-

Contamination concerns when cleaning pipes can be eliminated, and the complexity of cleaning work is reduced!

Improvement by theme

- Reduced time spent on work

- Enhanced safety

- Foreign substance contamination measures

Semiconductor and precision instrument workplaces

View all-

Improved installation efficiency using an open-ended wrench

Improvement by theme

- Reduced time spent on work

- Improved production efficiency

- Piping in tight spaces

-

Reduced replacement frequency for even greater cost reductions

Improvement by theme

- Reuse

- Cost reduction

-

Noise and coupling disconnection caused by vibration eliminated

Improvement by theme

- Reduced production problems

- Cost reduction

-

Damage avoided by preventing incidents caused by hose coupling leaks and disconnections

Improvement by theme

- Reduced production problems

- Cost reduction

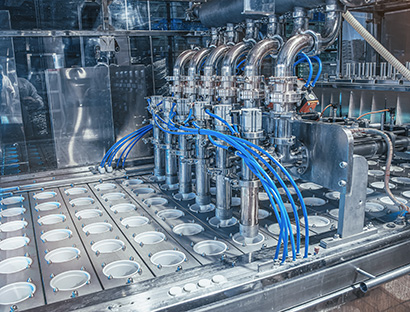

Food and beverage workplaces

View all-

Less color migration (coloration) in the hose and reduced cleaning time

Improvement by theme

- Foreign substance contamination measures

- Improved production efficiency

- Coloring and odor countermeasures

-

Issues caused by clamps were eliminated, enabling stable production

Improvement by theme

- Reduced production problems

- Cost reduction

- Improved production efficiency

-

Improving resistance to odors and fluid accumulation at couplings for increased production efficiency

Improvement by theme

- Foreign substance contamination measures

- Improved production efficiency

- Coloring and odor countermeasures

-

Leakage occurs when the hose clamp fastening is tightened!

Improvement by theme

- Reduced production problems

Machinery manufacturing workplaces

View all-

Eliminating oil leaks due to steel piping cracks caused by vibration, and making site operations easier

Improvement by theme

- Reduced production problems

- Piping in tight spaces

- Noise countermeasures

-

Inadequately tightened hose clamps can loosen over time and cause leaks

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Cost reduction

-

Sodium bicarbonate used in a cleaning machine causes hoses to wear and is very dangerous

Improvement by theme

- Reduced production problems

- Enhanced safety

- Cost reduction

-

Stiff hoses have to be softened with hot water before use

Improvement by theme

- Reduced time spent on work

- Improved production efficiency

Factory equipment piping

View all-

Resolving trouble caused by hose disconnections from a metal temperature controller to significantly improve productivity!

Improvement by theme

- Reduced production problems

- Piping in tight spaces

- Reduced product loss

-

Improved wear resistance prevents holes from forming and foreign matter from entering

Improvement by theme

- Reduced maintenance

- Foreign substance contamination measures

- Reduced product loss

-

Hose crimping products are safe, but disposal and cost issues are also problems

Improvement by theme

- Reuse

- Cost reduction

- Improved production efficiency

-

Improving productivity by eliminating hose collapse and water leaks from couplings

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Piping in tight spaces