-

Search Products

- Support and Downloads

- Inquire Now

For heat resistant and food

TOYOSILICONE-S2 HOSE

Model | TSIS2

Features

-

Pressure-resistant hose with excellent heat resistance

-

Ideal for foods and beverages as there is minimal impact on odor and taste

-

Kink- and collapse-resistant hoses for improved transport efficiency

-

Usable for vacuum applications

Related video

Download materials

Product features

-

Pressure-resistant hose with excellent heat resistance

A combination of a specially braided double structure and metal coil reinforcement provides high shape retention and allows it to be used for both pressure feeding and vacuum (suction) transfer.

These hoses support high-temperature fluids up to 150°C, and the inside of food grade hoses and floors can be washed (there are conditions regarding temperature and usage time, etc.).

Can be used as piping as they remain flexible even at -30°C.

Pressure-resistant hose with excellent heat resistance

A combination of a specially braided double structure and metal coil reinforcement provides high shape retention and allows it to be used for both pressure feeding and vacuum (suction) transfer.

These hoses support high-temperature fluids up to 150°C, and the inside of food grade hoses and floors can be washed (there are conditions regarding temperature and usage time, etc.).

Can be used as piping as they remain flexible even at -30°C. -

Ideal for foods and beverages as there is minimal impact on odor and taste

Non-toxic, safe and reliable for food products and beverage applications

Because these hoses have minimal odor and little elution that affects the fluid, they are safe for food and beverages, etc.

The SUS 316 reinforcement material means that there is minimal risk of rusting, for safe, worry-free, and sanitary performance.

Ideal for foods and beverages as there is minimal impact on odor and taste

Non-toxic, safe and reliable for food products and beverage applications

Because these hoses have minimal odor and little elution that affects the fluid, they are safe for food and beverages, etc.

The SUS 316 reinforcement material means that there is minimal risk of rusting, for safe, worry-free, and sanitary performance. -

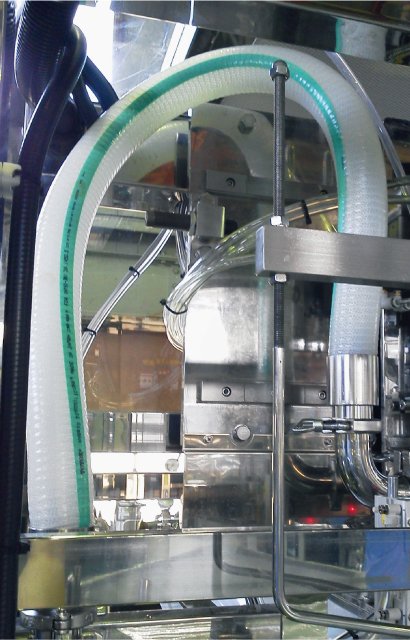

Kink- and collapse-resistant hoses for improved transport efficiency

Softer than the TOYOSILICONE-S Hose and resistant to kinking and collapse, making it ideal for bent piping and driving sections such as in filling machines.

Kink- and collapse-resistant hoses for improved transport efficiency

Softer than the TOYOSILICONE-S Hose and resistant to kinking and collapse, making it ideal for bent piping and driving sections such as in filling machines.

-

Compliant with various laws and regulations regarding safety and security

Compliant with the Food Sanitation Act (Public Notice No. 370, 1959) Registered with FDA DMF Type II No. 25486 Compliant with corrected RoHS 2 regulations

Compliant with various laws and regulations regarding safety and security

Compliant with the Food Sanitation Act (Public Notice No. 370, 1959) Registered with FDA DMF Type II No. 25486 Compliant with corrected RoHS 2 regulations

TOYOSILICONE-S2 HOSE

For heat resistant and food

| Application | For factory equipment (such as filling machines, cooling devices and heat-generating equipment) | |

|---|---|---|

| Fluid | ||

| Function |

Positive pressure (pressure feed) Negative pressure (vacuum) High-pressure-resistant Heat-resistant Cold-resistant Transparent Flexible Kinking/collapse prevention Oil-resistant (animal/vegetable oil) Oil-resistant (mineral oil) Chemical-resistant Low odor Low elution Non-adhesive Antistatic Dew condensation prevention Abrasion-resistant Flame retardant Plasticizer-free Disposal sorting not required |

|

| Regulatory | FDA registered RoHS 2 compliant Food Sanitation Act No. 370 compliant | |

| Specification | Main material | Silicone rubber |

| Reinforcing material | Polyester thread / SUS316 | |

| Inner diameter | 19.5mm~50.8mm | |

| Operating temperature range | -30℃~150℃ | |

| Other |

High water temp (under 100°C) / Steam (under 130°C for a short time) / Oils (animal and vegetable) (below 70°C) |

|

Specifications table by size Operating temperature range -30℃ 〜 150℃

| Model | Inner diameter × Outer diameter (mm) | Operating pressure (MPa) | Standard weight (kg/roll) | Standard length (m) | Minimum bending radius (mm) |

|---|---|---|---|---|---|

| TSIS2-19 | 19.5 × 31.5 | -0.1~0.7 | 6.7 | 10 | 100 |

| TSIS2-25 | 25.4 × 39 | -0.1~0.7 | 10.0 | 10 | 160 |

| TSIS2-32 | 32 × 47.5 | -0.1~0.7 | 14.1 | 10 | 200 |

| TSIS2-38 | 38.1 × 55 | -0.1~0.7 | 18.4 | 10 | 250 |

| TSIS2-50 | 50.8 × 69.5 | -0.1~0.3 | 12.4 | 5 | 350 |

Packing: Boxed Coloring: Milky white / green line added

*-0.1 MPa is an approximate value. The product may not be used for some applications. See "Vacuum Pressure Reference Region".

Related links

Precautions

Warning

TOYOX products have been developed and manufactured for a broad range of industrial applications. For applications that require safety, confirm in advance. Never use for implant or injection application or other applications where there is a possibility of the product partially remaining in the body. Toyox makes no guarantee of adaptability or safety related to such applications. Please read the Handling Precautions carefully before use.

(1) Under no circumstances should these hoses be used for nonpolar organic solvents (such as benzene, toluene and hexane), halogenated hydrocarbons (such as methylene chloride or trichloroethane), concentrated strong acids, strong bases, mineral oil or steam. Also, do not use for animal or vegetable oil at temperatures exceeding 70℃. For steam cleaning, apply for a short time with a saturated steam pressure of less than 0.(2) MPa at 130℃.

(2) Do not use for high temperature water at exceeding 100℃. Due to weakened reinforcement (thread), it can cause a hose puncture and secondary damage such as injury and burn.

(3) Note that silicone rubber has high gas permeability.Use caution when using this product with gases.Be sure to check “Precautions for Using Our Products Safely” before choosing a product.

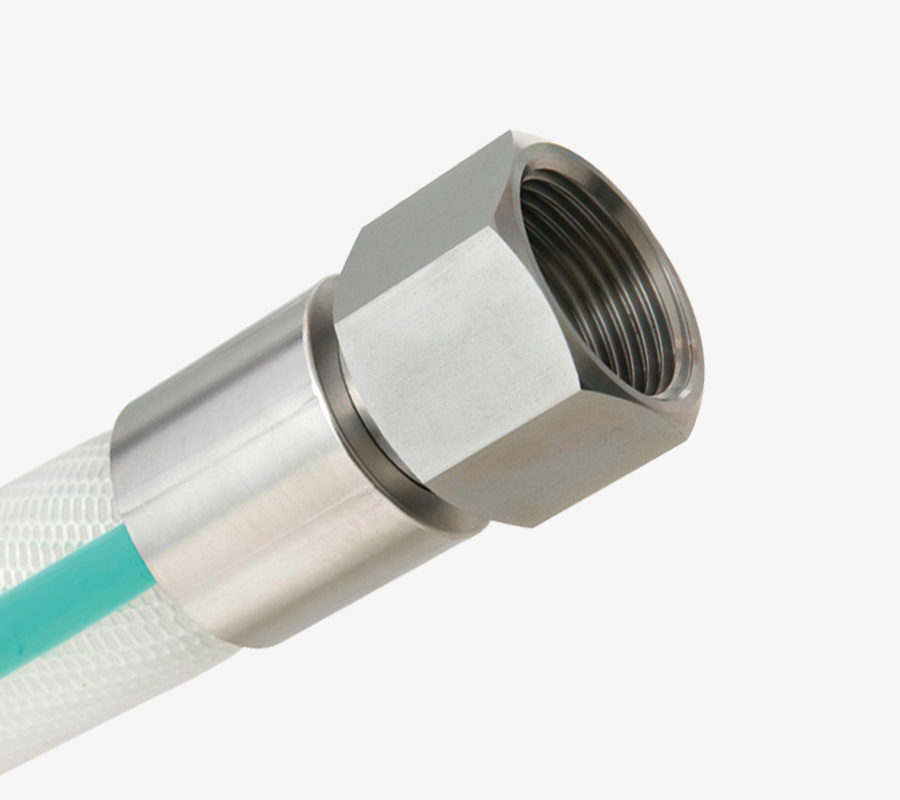

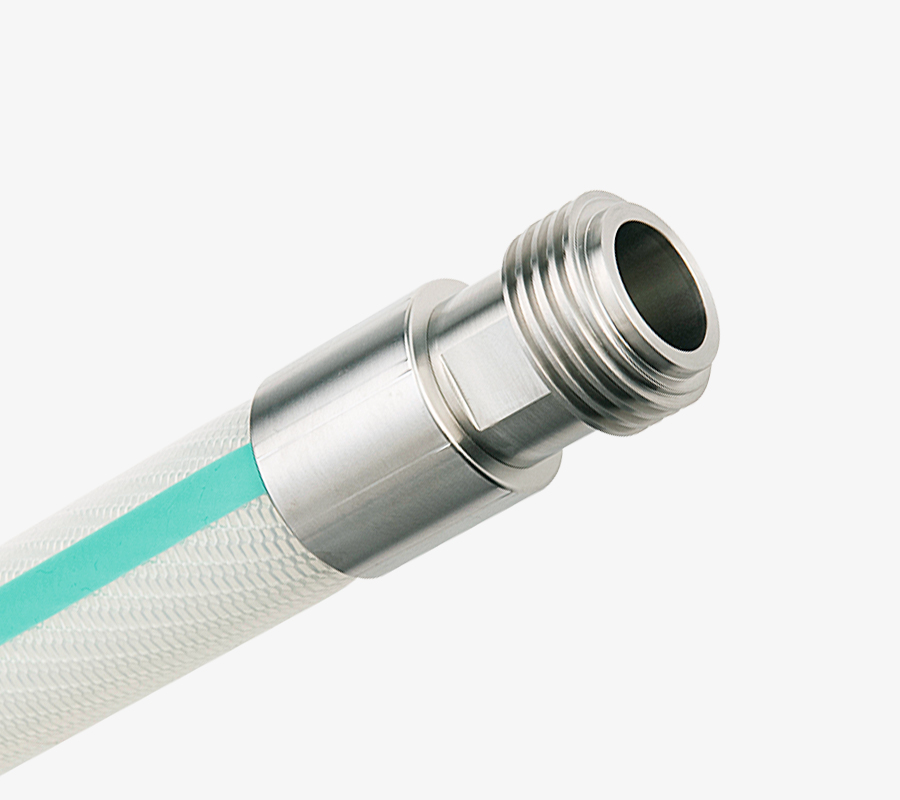

Compatible Couplings

| Hose details | Hose connection | Crimped | Crimped | Crimped | Crimped | Crimped | Crimped |

|---|---|---|---|---|---|---|---|

| Coupling specifications | Male thread | Female thread | Coupler | Ferrule | Male | Hexagon nut | |

| Main material |

Stainless steel

|

Stainless steel

|

Stainless steel

|

Stainless steel

|

Stainless steel

|

Stainless steel

|

|

| Model No. | H01 | H04 | HC | HF | HM | HNT | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

| TSIS2-19 |

19.5

31.5

|

◯ | ◯ | ◯ | ◯ | - | - |

| TSIS2-25 |

25.4

39

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TSIS2-32 |

32

47.5

|

- | - | ◯ | ◯ | ◯ | ◯ |

| TSIS2-38 |

38.1

55

|

- | - | ◯ | ◯ | ◯ | ◯ |

| TSIS2-50 |

50.8

69.5

|

- | - | ◯ | ◯ | ◯ | ◯ |

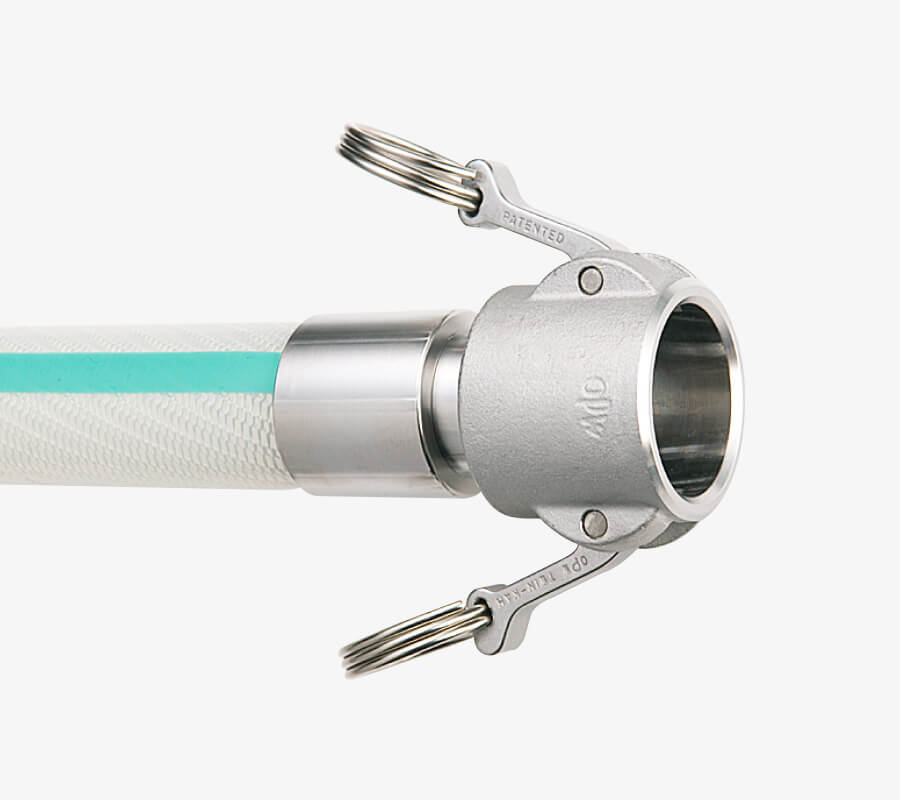

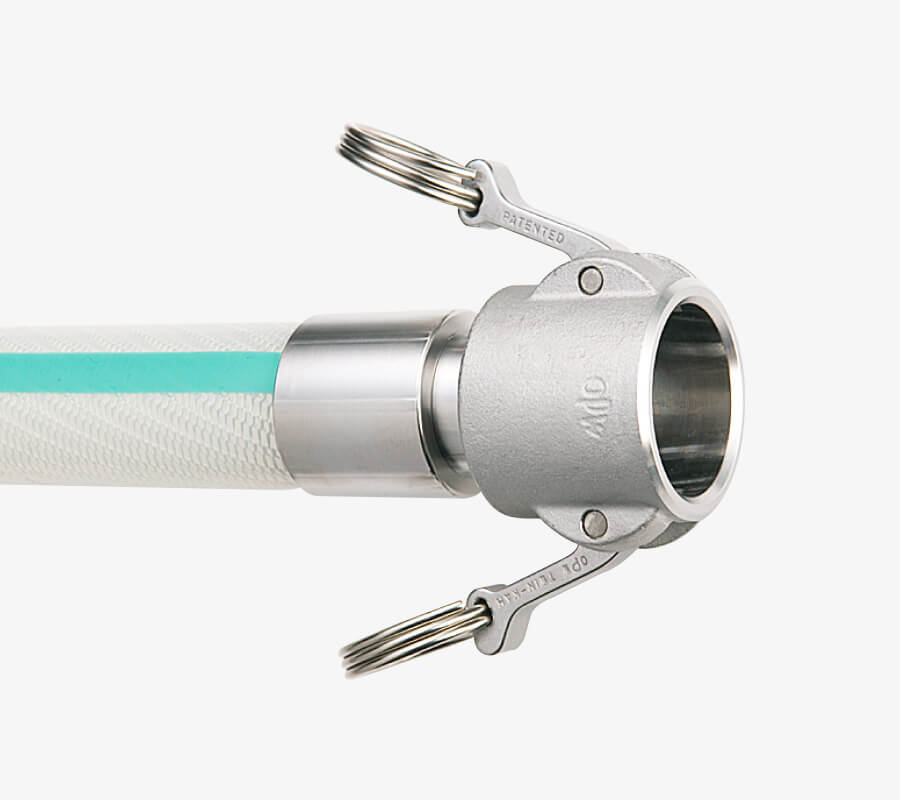

Compatible KAMLOK

| Hose details | Hose connection | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Crimped | Hose clamp tightening | Hose clamp tightening |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling specifications | Coupler | Coupler | Coupler | Coupler | Coupler | Adapter | Adapter | Coupler | Adapter | Coupler | |

| Main material |

Aluminum alloy

|

Resin (PP)

|

Stainless steel

|

Aluminum alloy

|

Stainless steel

|

Resin (PP)

|

Stainless steel

|

Stainless steel

|

Aluminum alloy

|

Resin (PP)

|

|

| Model No. | 633-C-AL | 633-C-PP | 633-C-SST | 633-CL-AL | 633-CL-SST | 633-E-PP | 633-E-SST | HC | 633-E-AL | 633-CL-PP | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

|

|

|

|

| TSIS2-19 |

19.5

31.5

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - |

| TSIS2-25 |

25.4

39

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TSIS2-32 |

32

47.5

|

◯ | - | ◯ | ◯ | ◯ | - | ◯ | ◯ | ◯ | - |

| TSIS2-38 |

38.1

55

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TSIS2-50 |

50.8

69.5

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |