-

Search Products

- Support and Downloads

- Inquire Now

anti-static

TOYOTOP-E HOSE

Model | TPE

Features

-

Retains its antistatic effects

-

Enables fluid conditions to be checked easily

-

Prevents static-related problems

-

Usable for vacuum applications

Download materials

Product features

-

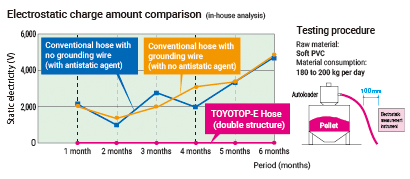

Retains its antistatic effects

Long-lasting antistatic effect that prevents clogging with powder or granular materials and improves productivity

Retains its antistatic effects

Long-lasting antistatic effect that prevents clogging with powder or granular materials and improves productivity

-

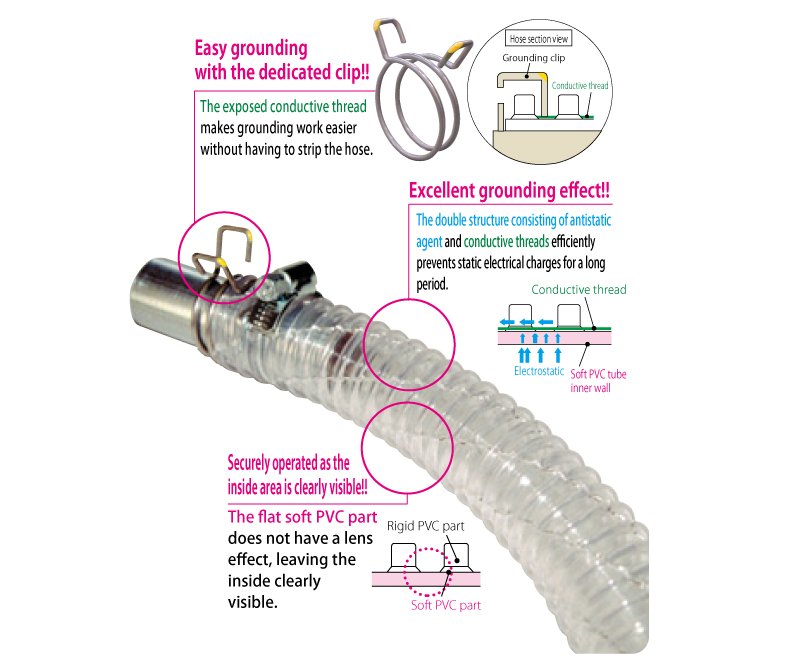

Enables fluid conditions to be checked easily

Because fluids do not stick to the inner surface of the hose, it is easy to see inside the transparent hose for effective verification.

Click here to check the transparency of the hose with a video

Enables fluid conditions to be checked easily

Because fluids do not stick to the inner surface of the hose, it is easy to see inside the transparent hose for effective verification.

Click here to check the transparency of the hose with a video

-

Prevents static-related problems

Elimination of unpleasant static discharge to the human body for safety Usable for suction and pressure feed applications

Prevents static-related problems

Elimination of unpleasant static discharge to the human body for safety Usable for suction and pressure feed applications

-

Reduced time spent on work

Attaching a dedicated grounding clip eliminates tedious stripping work for improved workability.

Reduced time spent on work

Attaching a dedicated grounding clip eliminates tedious stripping work for improved workability.

TOYOTOP-E HOSE

anti-static

| Application | For feeding powders for plastic molding equipment / Anti Static | |

|---|---|---|

| Fluid | ||

| Function |

Positive pressure (pressure feed) Negative pressure (vacuum) High-pressure-resistant Heat-resistant Cold-resistant Transparent Flexible Kinking/collapse prevention Oil-resistant (animal/vegetable oil) Oil-resistant (mineral oil) Chemical-resistant Low odor Low elution Non-adhesive Antistatic Dew condensation prevention Abrasion-resistant Flame retardant Plasticizer-free Disposal sorting not required |

|

| Regulatory | RoHS 2 compliant | |

| Specification | Main material | Soft PVC |

| Reinforcing material | Rigid PVC | |

| Inner diameter | 32mm~63.5mm | |

| Operating temperature range | -10℃~50℃ | |

| Other | ||

Specifications table by size Operating temperature range -10℃ 〜 50℃

| Model | Inner diameter × Outer diameter (mm) | Operating pressure (MPa) | Standard weight (kg/roll) | Standard length (m) | Minimum bending radius (mm) |

|---|---|---|---|---|---|

| TPE032-20 | 32 × 41.6 | -0.1~0.15 | 7.4 | 20 | 100 |

| TPE038-20 | 38 × 48.4 | -0.1~0.15 | 9.6 | 20 | 120 |

| TPE050-20 | 50.8 × 63 | -0.1~0.1 | 16.0 | 20 | 200 |

| TPE065-20 | 63.5 × 78.9 | -0.1~0.1 | 25.0 | 20 | 260 |

Packing: film packing

*Depressurization deformation temperature is the temperature at which the hose deforms when its interior (in a straight condition) is depressurized to -0.1 MPa (-760 mmHg). It is not the hose's use limit temperature. *-0.1 MPa is an approximate value. The product may not be used for some applications. See "Vacuum Pressure Reference Region".

TOYOTOP-E grounding clip (made specifically for the TOYOTOP-E HOSE)

| Part Number | Applicable hose | Packing unit (pc) | |

|---|---|---|---|

*This is not a hose clamp. |

TPEC-032 | TPE032-20 | 10 |

| TPEC-038 | TPE038-20 | ||

| TPEC-050 | TPE050-20 | ||

| TPEC-065 | TPE065-20 |

Here for attachment instructions.

Related links

Precautions

* TOYOTOP-E Hose should be used with dedicated ground clips to effectively prevent static electricity over long periods.

-

Pharmaceutical / Cosmetic / Chemical workplaces

Tens of thousands of bolts become charged with static electricity, a hazard to the workerseven after being crushed

- Reduced time spent on work

- Enhanced safety

- Antistatic measures

-

Pharmaceutical / Cosmetic / Chemical workplaces

Static electricity causes powder to stick to the hose, reducing production efficiency

- Enhanced safety

- Improved production efficiency

- Antistatic measures

Compatible KAMLOK

| Hose details | Hose connection | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening | Hose clamp tightening |

|---|---|---|---|---|---|---|---|---|---|---|

| Coupling specifications | Coupler | Coupler | Coupler | Coupler | Adapter | Adapter | Coupler | Coupler | Adapter | |

| Main material |

Aluminum alloy

|

Stainless steel

|

Aluminum alloy

|

Stainless steel

|

Stainless steel

|

Aluminum alloy

|

Resin (PP)

|

Resin (PP)

|

Resin (PP)

|

|

| Model No. | 633-C-AL | 633-C-SST | 633-CL-AL | 633-CL-SST | 633-E-SST | 633-E-AL | 633-C-PP | 633-CL-PP | 633-E-PP | |

| Hose model |

Inner

diameter (mm) Outer

diameter (mm) |

|

|

|

|

|

|

|

|

|

| TPE032-20 |

32

41.6

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |

| TPE038-20 |

38

48.4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TPE050-20 |

50.8

63

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TPE065-20 |

63.5

78.9

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | - | - |