Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Pharmaceutical / Cosmetic / Chemical workplaces

Improvement Case

Case studiesPharmaceutical / Cosmetic / Chemical workplaces

Pharmaceutical / Cosmetic / Chemical workplaces

Tens of thousands of bolts become charged with static electricity, a hazard to the workerseven after being crushed

- Improvement by theme

-

Reduced time spent on work

Enhanced safety

Antistatic measures

- Fluid/Application

-

Powders

- Product name

-

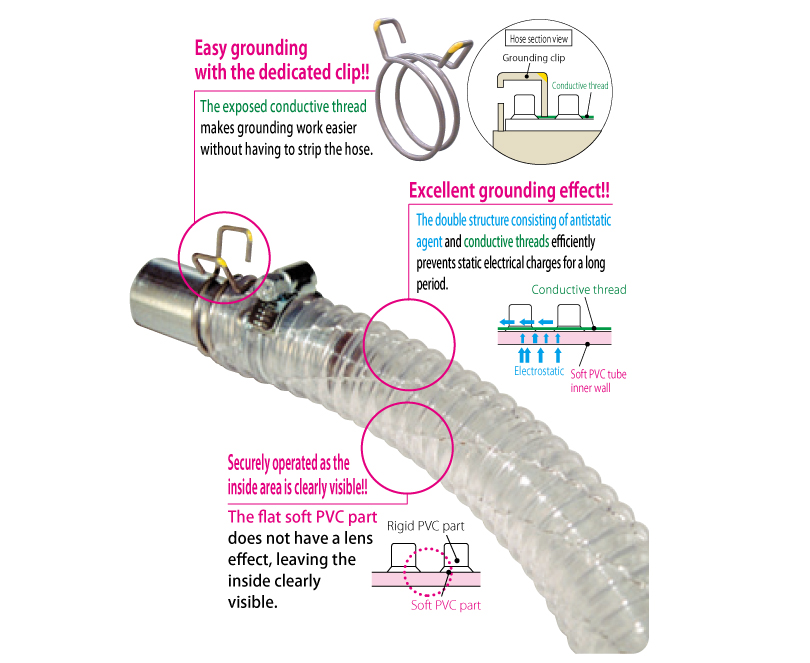

TOYOTOP-E HOSE

- Product type

-

Industrial hoses

Before[ Suction hose ]

At a chemical production plant, they were using suction hoses to transport wet powdered chemicals before they reached the drying oven. One day, they measured the static electricity and found a charge between 20 and 30 kilovolts, an extremely dangerous level for human workers.

After[ TOYOTOP-E HOSE ]

When it was replaced with the antistatic TOYOTOP-E Hose and the static electricity was measured, it was confirmed that the effect was significant. It was switched as dedicated ground clips enabled easy grounding. It provided peace of mind to the work process.