Improvement Case

Case studies

IMPROVEMENT CASE

-

Less odor transferred to hoses, less liquid pooling in couplings, and increased work productivity!

Improvement by theme

- Cost reduction

- Reduced maintenance

- Coloring and odor countermeasures

-

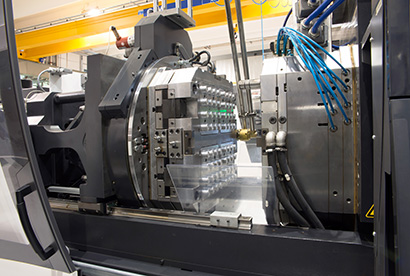

Friction opens up holes in the hose, preventing stable supply of raw materials

Improvement by theme

- Reduced production problems

- Improved production efficiency

- Antistatic measures

-

Less color migration (coloration) in the hose and reduced cleaning time

Improvement by theme

- Foreign substance contamination measures

- Improved production efficiency

- Coloring and odor countermeasures

-

Tens of thousands of bolts become charged with static electricity, a hazard to the workerseven after being crushed

Improvement by theme

- Reduced time spent on work

- Enhanced safety

- Antistatic measures

-

Fluid leakage in a high-temperature (80°C) vacuum environment

Improvement by theme

- Enhanced safety

- Specification comparison

-

Parts replaced to prevent hose disconnections and leaks from couplings, in order to help prevent work-related burn injuries

Improvement by theme

- Reduced production problems

- Enhanced safety

-

I want to change hoses to meet the revised Food Sanitation Act, but oils & fats remain a problem

Improvement by theme

- Reduced time spent on work

- Foreign substance contamination measures

- Laws and regulations

-

Eliminating leaks from couplings, and improving hose ease-of-use and workability

Improvement by theme

- Improved workability

- Reduced production problems

- Foreign substance contamination measures

-

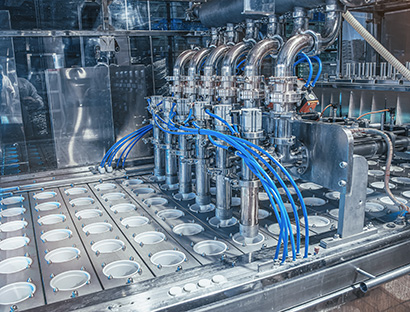

Machinery vibration causes sanitary beverage hoses to become displaced and make a lot of noise!

Improvement by theme

- Sanitary measures

-

Eliminating leakage problems, and making piping work easier and faster

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Cost reduction