-

Search Products

- Services and Downloads

- Inquire Now

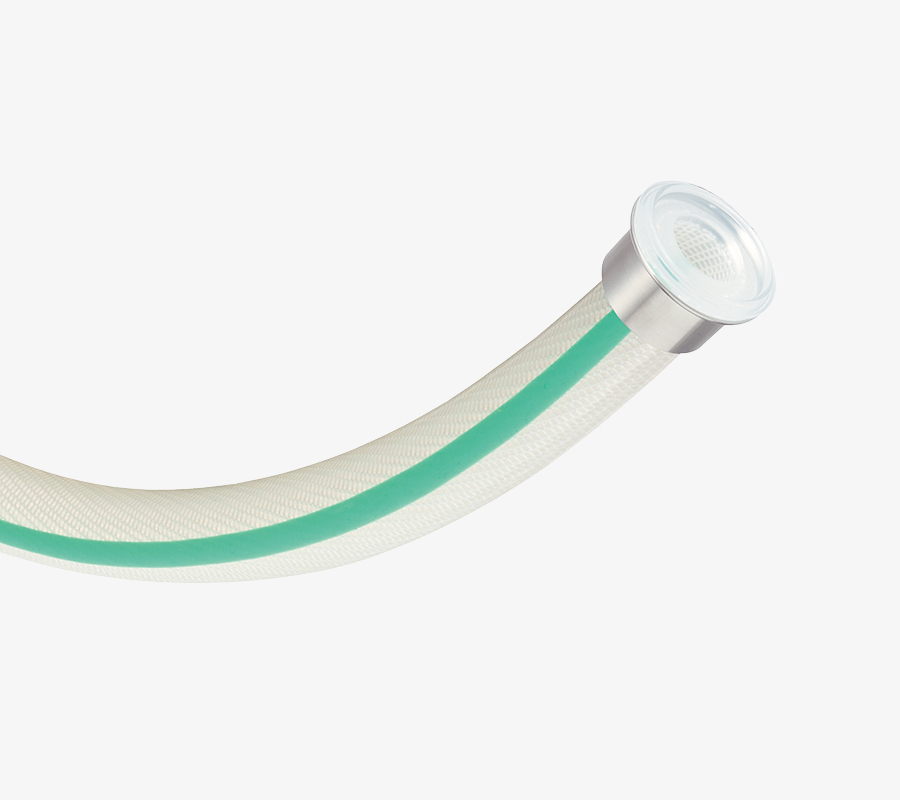

Couplings for plant facility piping (for TOYOSILICONE Hose Series)

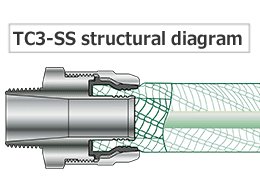

TOYOCONNECTOR TC3-SS

- Model | TC3-SS

- Material | Stainless steel

Features

-

Leak and disconnection prevention

-

Energy-saving

-

Reduced time spent on piping work

-

Hygienic

Related video

Download materials

Product features

-

Leak and disconnection prevention

The unique construction allows the hose to be securely inserted to the base of the coupling, preventing hose disconnections and fluid leaks.

Leak and disconnection prevention

The unique construction allows the hose to be securely inserted to the base of the coupling, preventing hose disconnections and fluid leaks.

-

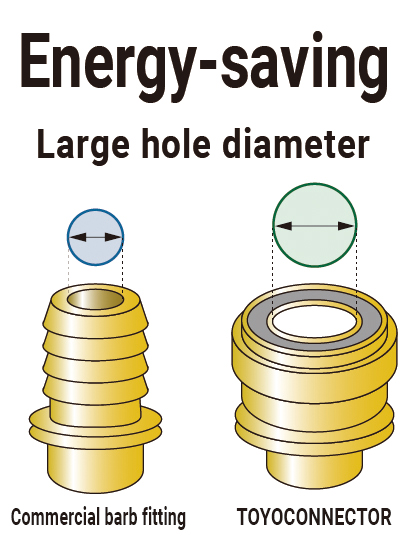

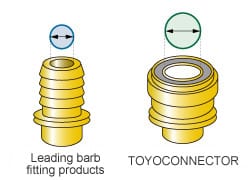

Energy-saving

Larger effective sectional area of the hose nozzle than barb fittings for reduced pressure loss and minimal power consumption.

Energy-saving

Larger effective sectional area of the hose nozzle than barb fittings for reduced pressure loss and minimal power consumption.

-

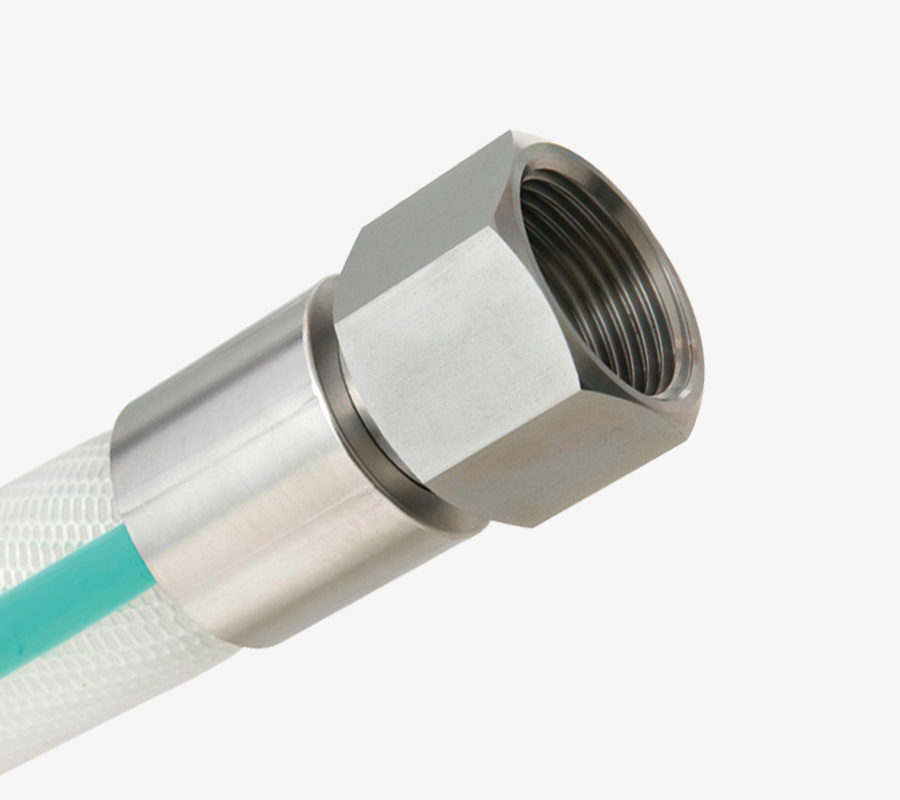

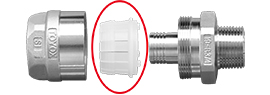

Reduced time spent on piping work

No retightening is required and installation is easy. Simply tighten the nut until there are no gaps.

Reduced time spent on piping work

No retightening is required and installation is easy. Simply tighten the nut until there are no gaps.

-

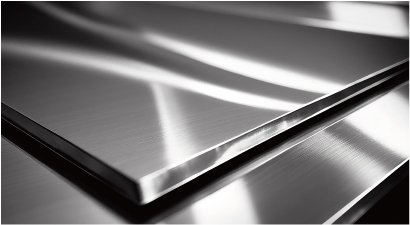

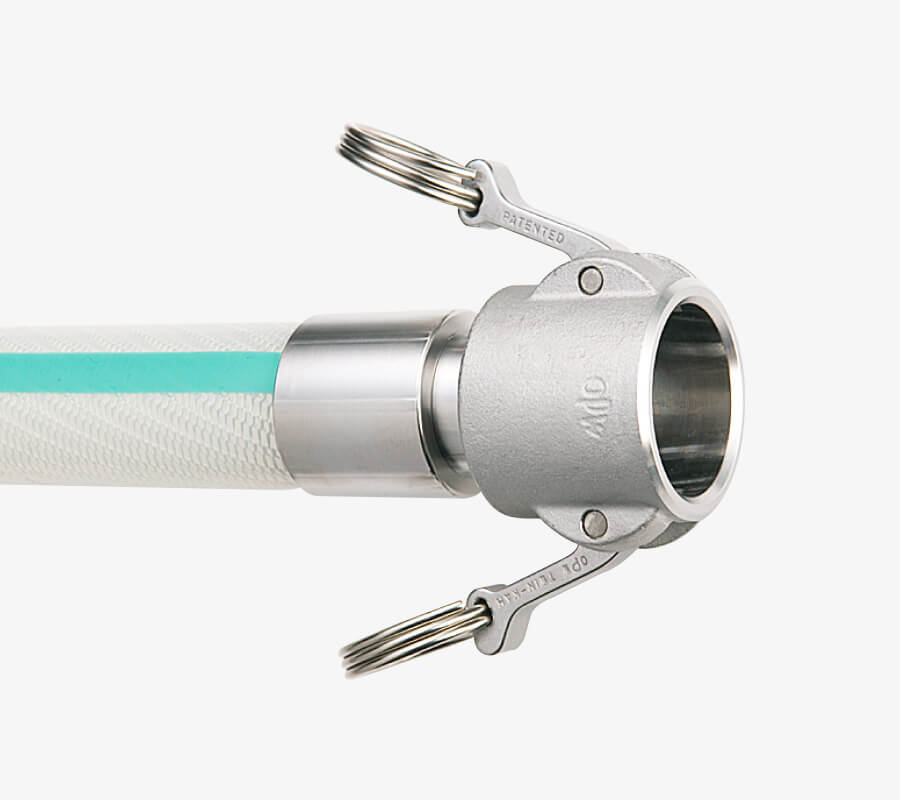

Hygienic

Made of rust-resistant, hygienic SCS13 (equivalent to SUS 304) stainless steel.

Hygienic

Made of rust-resistant, hygienic SCS13 (equivalent to SUS 304) stainless steel.

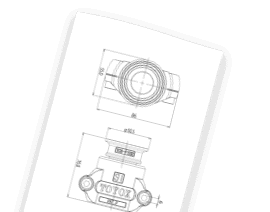

TOYOCONNECTOR TC3-SS

Couplings for plant facility piping (for TOYOSILICONE Hose Series)

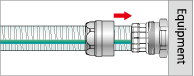

- Hose side

- Cap nut

- Hose inner diameter (mm)

- 9, 12, 15, 19, 25

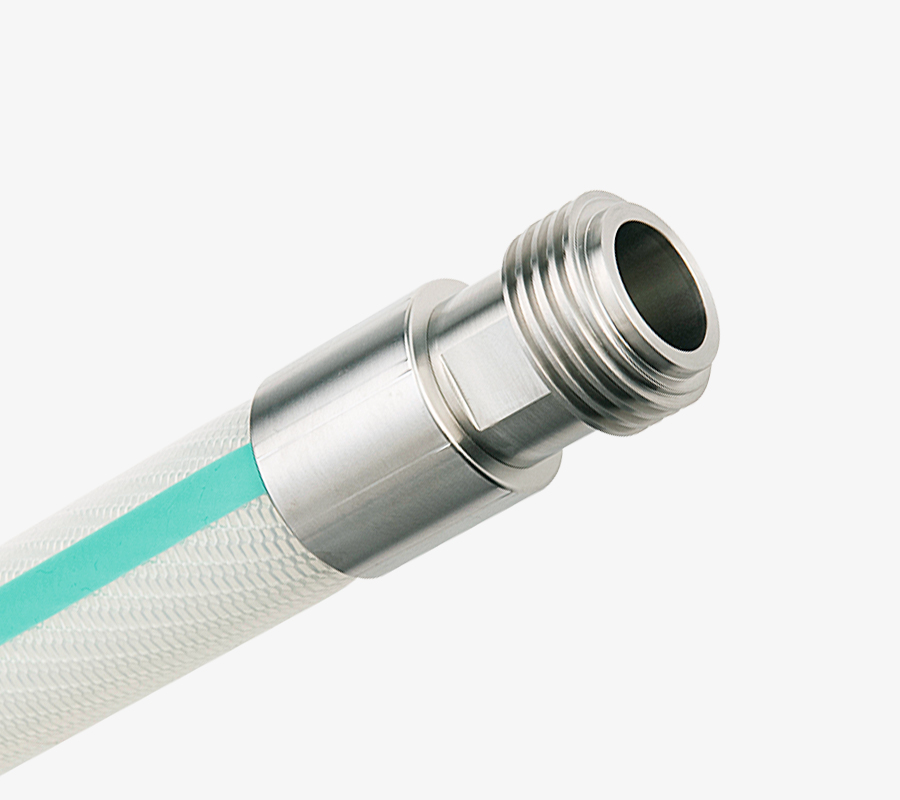

- Device side

- Male thread

- Connection size

- R3/8, R1/2, R3/4, R1

| Model No. | TC3-SS | |

|---|---|---|

| Main material | ||

| Function | ||

| Fluid | Water (non-potable) Air Oil Chemicals and cosmetics | |

| Legal compliance | RoHS 2 compliant | |

| Material details | Cap nut | SCS13 (SUS304 equivalent) |

| Nipple | SCS16 (SUS316L equivalent) | |

| Sleeve | PVDF | |

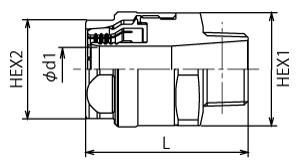

Coupling specifications

| Model | Compatible hose inner diameter (mm) |

Thread standard | Dimensions (mm) | Weight (g) | No. of packaged items | |||

|---|---|---|---|---|---|---|---|---|

| HEX1 | HEX2 | L | Φd1 | |||||

| TC3-SS9-R3/8 | 9 | R3/8 | 28 | 24.2 | 48 | 6.9 | 133 | 20 |

| TC3-SS12-R1/2 | 12 | R1/2 | 32 | 27 | 53 | 10.1 | 178 | 20 |

| TC3-SS15-R1/2 | 15 | R1/2 | 36 | 30.8 | 55 | 13.3 | 217 | 20 |

| TC3-SS19-R3/4 | 19 | R3/4 | 41 | 35.8 | 59.5 | 16.9 | 290 | 10 |

| TC3-SS25-R1 | 25 | R1 | 50 | 43.8 | 66 | 22.8 | 438 | 10 |

Related links

Precautions

*When installing, do not use a liquid screw sealant containing a solvent.

Compatible Hoses: 6

|

Hose name | TOYOSILICONE HOSE | TOYOSILICONE STEAM HOSE | TOYOSILICONE THERMO HOSE | HYBRID TOYOSILICONE HOSE | TOYOSILICONE-P HOSE | TOYOSILICONE-S HOSE |

|---|---|---|---|---|---|---|---|

| Main material | Silicone rubber | Silicone rubber | Silicone rubber | Silicone rubber | Silicone rubber | Silicone rubber | |

| Operating temperature range | -30℃~150℃ | -30℃~140℃ | -30℃~120℃ | -30℃~130℃ | -30℃~100℃ | -30℃~150℃ | |

| Model No. | TSI | TSISTM | TSITH | HTSI | TSIP | TSIS | |

| Coupling model |

Compatible hose nominal inner diameter (mm)

Coupling specifications

|

|

|

|

|

|

|

| TC3-SS9-R3/8 |

9

R3/8

|

◯ | ◯ | ◯ | - | - | - |

| TC3-SS12-R1/2 |

12

R1/2

|

◯ | ◯ | ◯ | ◯ | ◯ | - |

| TC3-SS15-R1/2 |

15

R1/2

|

◯ | ◯ | ◯ | ◯ | ◯ | - |

| TC3-SS19-R3/4 |

19

R3/4

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TC3-SS25-R1 |

25

R1

|

◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Replacement Sleeve Set | Part Number | Packing Unit |

|---|---|---|

| pc | ||

|

TC3-SS9-S | 20 |

| TC3-SS12-S | 20 | |

| TC3-SS15-S | 20 | |

| TC3-SS19-S | 10 | |

| TC3-SS25-S | 10 |

- 材質 /

- Sleeve : PVDF

Attachment Tool

Use a wrench such as a regular adjustable or monkey wrench to finish tightening. Do not, however, use a pipe wrench as it will damage the nut portion.