Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

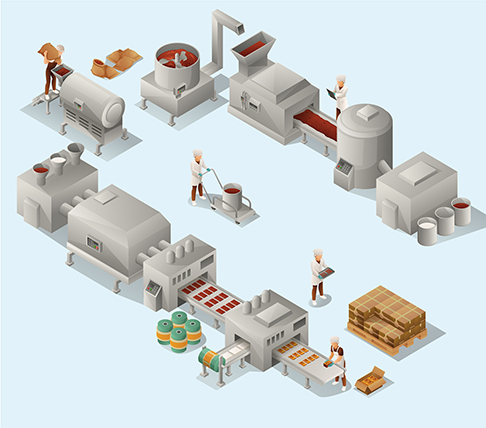

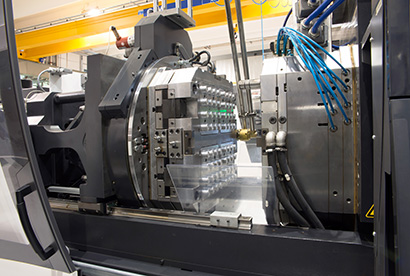

Plastic molding workplaces

Significantly increased productivity and safety by preventing hose degradation and coupling disconnection/leakage

- Improvement by theme

-

Improved workability

Enhanced safety

Reduced product loss

- Fluid/Application

-

Water (non-potable)

Heat-resistant

- Product name

-

TOYOSILICONE STEAM HOSE

/

TOYOCONNECTOR TC3-SS

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ Silicone hose / Threaded hose nipple / Hose clamp ]

The customer was using a heat-resistant silicone hose connected with a barb hose clamp to transport hot water (120°C) for a plastic molding machine. However, the hose began to crack in less than one year of installation, and issues such as coupling disconnection and leaks were also occurring. The customer needed to do something to prevent production loss and work injuries caused by burns.

After[ TOYOSILICONE STEAM HOSE / TOYOCONNECTOR TC3-SS ]

The customer decided to install TOYOSILICONE Steam Hose (with heat resistance up to 140°C) and TOYOCONNECTOR to prevent disconnections and leaks. After switching the old parts out, the customer experienced less hose degradation due to heat, and therefore had to replace the hose less often. The new parts also eliminated disconnections and leaks, allowing the customer to stabilize production, help prevent burns, and increase productivity.