Improvement Case

Case studies

IMPROVEMENT CASE

Search criteria

Industry

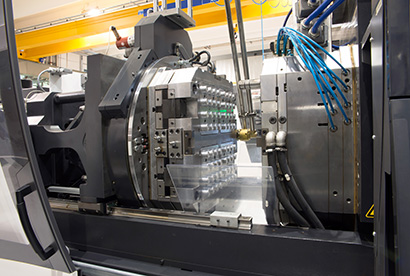

Plastic molding workplaces

-

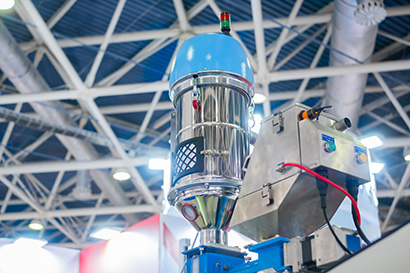

Improved wear resistance prevents holes from forming and foreign matter from entering

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Reduced product loss

-

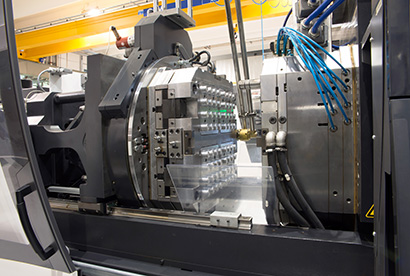

Friction opens up holes in the hose, preventing stable supply of raw materials

Improvement by theme

- Reduced production problems

- Improved production efficiency

- Antistatic measures

-

The improved anti-static design shortens cleaning times for greater work efficiency

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Antistatic measures

-

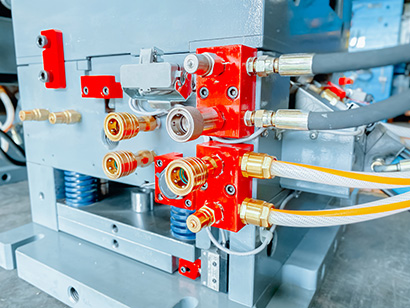

Significantly increased productivity and safety by preventing hose degradation and coupling disconnection/leakage

Improvement by theme

- Improved workability

- Enhanced safety

- Reduced product loss

-

Heat leads to hose collapse, preventing stable supply of raw materials

Improvement by theme

- Reduced production problems

- Foreign substance contamination measures

- Antistatic measures

-

Raising the mold temperature causes liquid to leak onto the product, resulting in product defects

Improvement by theme

- Reduced production problems

- Reduced product loss

-

Eliminating leakage problems, and making piping work easier and faster

Improvement by theme

- Reduced time spent on work

- Reduced production problems

- Cost reduction

-

Hose interior material wears away, causing holes and requiring frequent hose replacement

Improvement by theme

- Reduced maintenance

- Foreign substance contamination measures

- Improved production efficiency