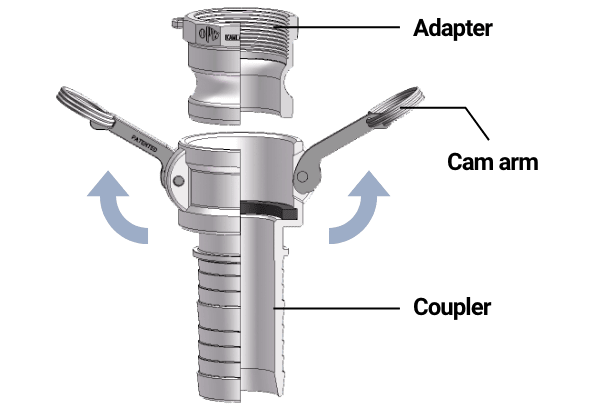

Basic operation method

KAMLOK is an arm-type (lever-type) coupling consisting of a male adapter and female coupler that can be easily attached and detached by tightening or loosening the lever arm.

-

1Push up the coupler’s cam arm to its highest position and insert it into the adapter.

-

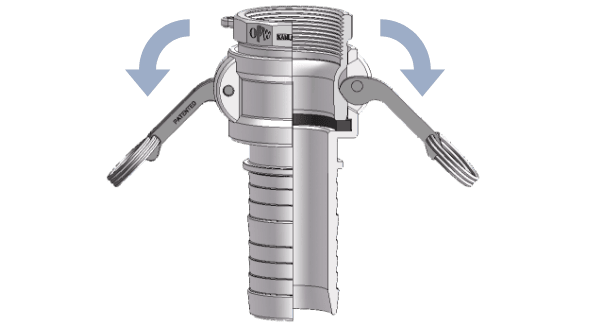

2Lower both cam arms at the same time. (Pushing down one side at a time may cause the rear cam arm to be too stiff to close.)

-

3Lower the cam arms until they make firm contact with the body. This completes connection. When detaching, raise both cam arms at the same time.

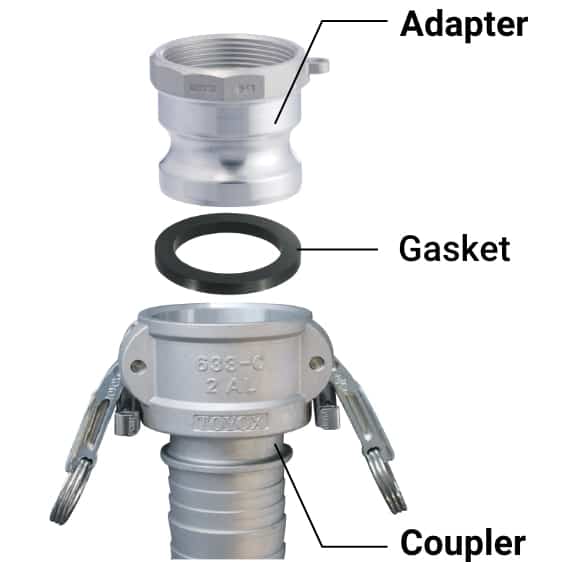

Connection type

Some KAMLOK couplings are used to connect to hoses, devices, equipment, and piping.

| Female thread |

Male thread |

Hose shank |

Dust cap/plug | Flange | |

|---|---|---|---|---|---|

| Adapter |  |

|

|

|

|

| Coupler |  |

|

|

|

|

Material

Products are available in aluminum alloy, stainless steel, bronze, and polypropylene (PP) to suit a variety of applications, fluids, and operating conditions.

-

Aluminum alloy (AL) -

Stainless steel (SST) -

Polypropylene (PP) -

Bronze (BR)

Advantages

-

Advantage 01

Easy attachment/detachment, reduced time spent on work

For attachment/detachment, simply insert the adapter into the coupler and pull the cam arms on the coupler. Work can be completed in mere seconds, significantly reducing working time compared with threaded joint systems.

-

Advantage 02

Standardization of work and cost reductions

Attachment/detachment can be performed by a single person and without having to select an alignment position, eliminating both the need for advanced skills and the risk of mishandling.

Also, wear and tear on the threads and damage to the hose are minimized in comparison with threaded joint systems, allowing for reduced maintenance and personnel costs.

-

Advantage 03

Unique seal structure for safety and security

In addition to being incredibly airtight, KAMLOK also prevents accidents such as leakages that could cause fires, explosions, or air pollution by eliminating wear and connection failures that are seen in threaded joint system.

We also offer a TWINLOK type with an arm locking function that prevents the arms from coming off in the unlikely event of failure.

-

Advantage 04

Improving work environments

KAMLOK reduces worker load and improve employee health by enabling working to be completed in a far shorter time, even when being attached or detached in food refrigerators.

-

Advantage 05

Usable with any fluid

KAMLOK comes in four materials: aluminum, stainless steel, polypropylene, and bronze. Select a material that suits the matter being conveyed, whether it be fluids, powder and granular materials, or gases.

-

Advantage 06

Maintaining product quality while reducing loss

Stainless steel KAMLOKs are widely used in the food industry. The ability to attach and detach the couplers in just seconds prevents deterioration in product quality and minimizes product loss due to leakage.

-

Advantage 07

Reliability and compatibility trusted in 160 countries

The ability to combine the coupler with any type of hose with the same bore size also makes it economical and accounts for why it is used in all types of fluid transport sites across the globe.

* Note: This assumes that connections are made between products of the same material. -

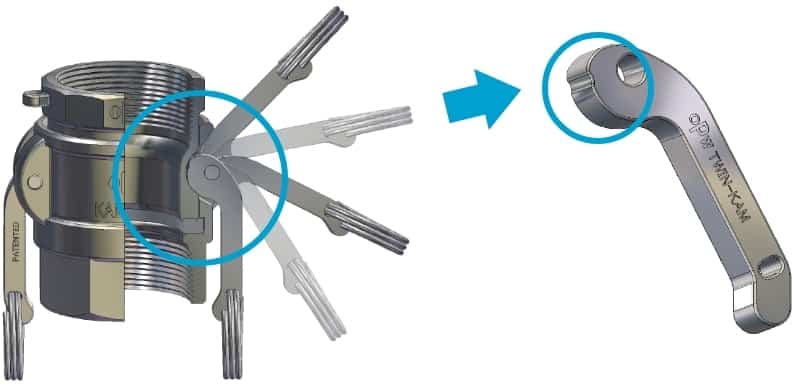

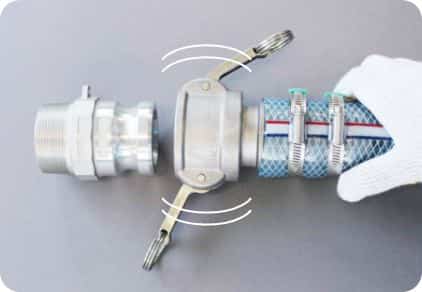

Advantage 08

Improved workability

Unlike conventional products, smooth coupling connections with a cam arm ring do not get caught between the hose and cam arm.

Conventional

The arms can be difficult to close due to contact with the ring

KAMLOK

No contact with the ring for smooth operation

Reasons why KAMLOK is safe

-

Only KAMLOK has the twin cam structure capable of preventing accidents!

Two-stage tightening system with unique twin cam arm shape that prevents unexpected detachment of couplings. Convenient one-touch attachment/detachment makes work safer, more secure, and speedy!

-

The arms stop at 45°

KAMLOK twin cam arm stop position of 45° to hold the adapter securely in place and prevent fluid leakage even if the cam arm loosens due to vibration or other causes.

* This does not completely prevent unexpected coupling detachments.

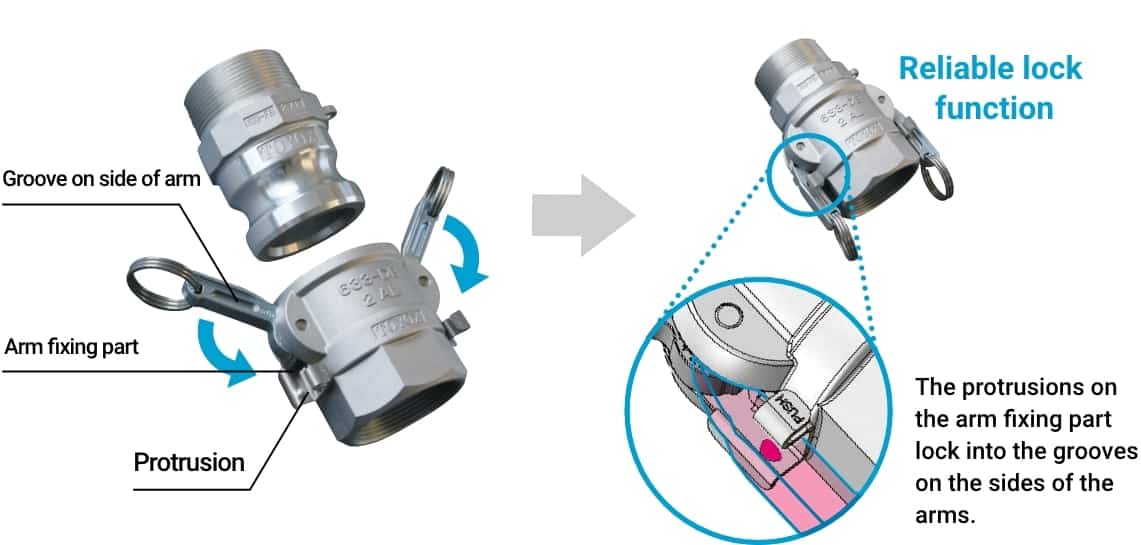

Why TWINLOK

is safer

Have you ever had to tie arms down because you were worried about couplings becoming detached? KAMLOK TWINLOK automatically locks when the arms are fastened. No more worries about couplings becoming loose or detached during connection.

-

POINT01

Arms don’t loosen, ensuring safety

- It easily locks the arm and prevents unexpected loosening or detachment of arm, ensuring safety and reliability.

- The “click” of the lock indicates lock engagement, confirming safety and providing peace of mind.

- Improved workability eliminates the need to tie up the arms with wire or string to prevent detachment.

Conventional

Arms tied down to prevent couplings from becoming detached.

TWINLOK

Arms are tightened and completely locked.

-

POINT02

Easy to attach and detach for improved workability

The arms can be temporarily fixed in the open position, making connection work that much easier.

Conventional

The wandering arms make work difficult.

TWINLOK

The arms are held open!

Easy release!

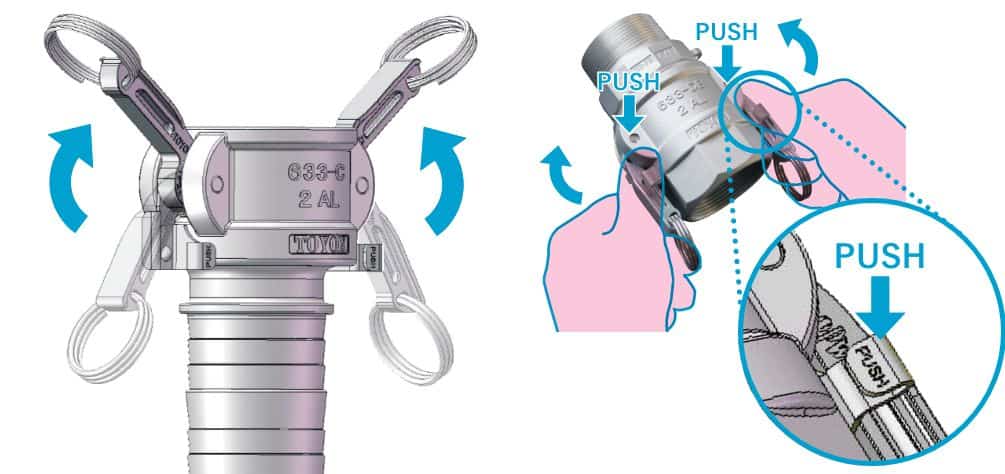

Open the arms while pressing “PUSH” stamped on the arm fixing part.

Main examples of past applications

- Steel

manufacturing - Material supply pipes used when repairing furnaces of cooling water piping for blast furnaces and converters. etc.

- Food

- General applications, pipe cleaning, food supply piping

- Oil

refining - Refineries, oil tanks, distribution facilities, tanker trucks, gas stations

- Ships

- Supply and drainage of oil and water, loading and unloading of seafood

- Chemicals

- General applications, production lines, cleaning piping, drainage lines

- Civil

engineering - Concrete, supply and drainage of water, removal of soil

- Agricultural machinery

- For spraying pesticides and water, fertilizer supply, irrigation

- Vehicles

- Tanker trucks, freight cars, sanitary food transport vehicles, beverage tankers, powder and granular transport vehicles

- Pharmaceuticals

- Product lines, cleaning piping

- Aviation

- Piping for oil, water and air