FAQ

FAQ

FAQ

Search criteria

Product type

hose

Search results

44matches

- Q Is there a hose that can be used for fuel oil? Fluid

-

A.

We do not provide hoses that can be used with fuel oil such as gasoline, light oil and heavy oil.

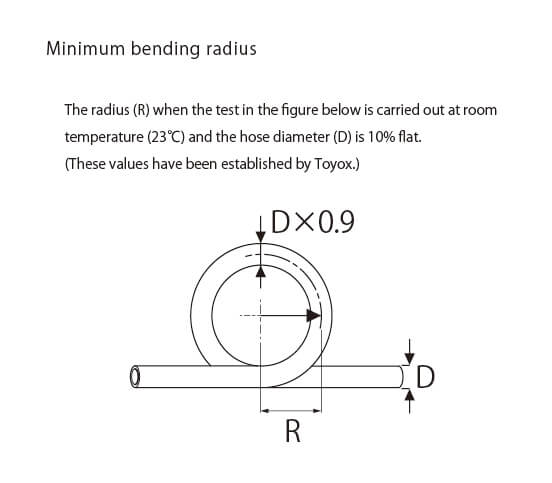

- Q Does the minimum bending radius refer to the length from the center point to the inside of the hose? Standard

-

A.

The minimum bending radius refers to the length from the center point to the center of the hose.

- Q Some hoses are marked “R2” and others “RoHS2”. What is the difference? Laws and regulations

-

A.

Both markings indicate compliance with RoHS2. Toyox began marking RoHS2-compliant hoses with “R2” beginning with products produced in 2017. However, we switched later on that same year to printing “RoHS2” in order to clarify the meaning.

- Q Where can I buy TOYOX products? Service

-

A.

Sorry for your inconvenience, but please contact us from our homepage inquiry form.

- Q My TOYOFUSSO Hose does not have a line printed on it like the products shown on your website. Is there any difference in performance? Specification

-

A.

We switched the outer material for TOYOFUSSO Hose from soft PVC to polyurethane beginning with products produced in November 2018. Products since then have a line (image line) printed on them. This improved heat resistance performance from 70°C to 80°C.

- Q Are your silicone hoses compliant with Food Sanitation Act No. 196 (PL System)? Can you provide a certificate of compliance? Laws and regulations

-

A.

Food Sanitation Act No. 196 (PL System) applies to synthetic plastic. This does not include silicon rubber. Toyox silicone hoses are compliant with Food Sanitation Act No. 595. Certificates of compliance are available for download by registered members (free).

- Q Can the TOYOSILICONE Hose handle conveying steam? Fluid

-

A.

No, the TOYOSILICONE is not designed for steam. The TOYOSILICONE Hose can handle up to 130℃ and 0.2 MPa of pressure, but this should be limited to short periods of time for sterilization purposes, and continuous use should be avoided. In addition, temperature and other conditions vary depending on product, so be sure to check the precautionary material for details.

- Q I would like to know the guideline for replacing the hose. Specification

-

A.

It depends on the usage environment and usage conditions (fluid, temperature, pressure, size, hose type, etc.). Check for deformation, hardening, discoloration, leakage, etc. by pre-start inspection and regular inspection, and replace or maintain if necessary. There is also a method to set the scheduled replacement date based on the initial replacement period and the past replacement frequency.

- Q Are the TOYOX hoses compatible with RoHS2? Laws and regulations

-

A.

All hoses (standard products) are RoHS2 compatible. Survey reports are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q I would like to know the price of TOYOX products, what should I do? Service

-

A.

Sorry for your inconvenience, but please contact us from our homepage inquiry form.

We provide a wide range of support from selecting ideal products for specific usage conditions to downloading certificates regarding laws and regulations, as well as downloading of materials such as catalogs.

You can download useful materials that address issues such as “leaks and disconnections”, “energy-saving measures”, and “odor and coloration.”

We use videos to introduce the benefits of using products and how to install them, which may be difficult to understand just using text and illustrations.

We have compiled frequently asked questions from customers in the “FAQ” section.

To assist you in making selections, we provide common examples of improvements for hoses and couplings through industry-based case studies.