FAQ

FAQ

FAQ

Search criteria

Product type

kamlok

Search results

22matches

- Q Are there any products such as lids to prevent foreign matter from entering into the KAMLOK couplings? Model lineup

-

A.

For each material, the Dust Cap 634-B is available for couplers and the Plug Cap 634-A for adapters.

However, they cannot be used in applications where pressure is applied or to prevent leakage. It is only for protection from dust and foreign matter. - Q What kind of coupling is KAMLOK? Specification

-

A.

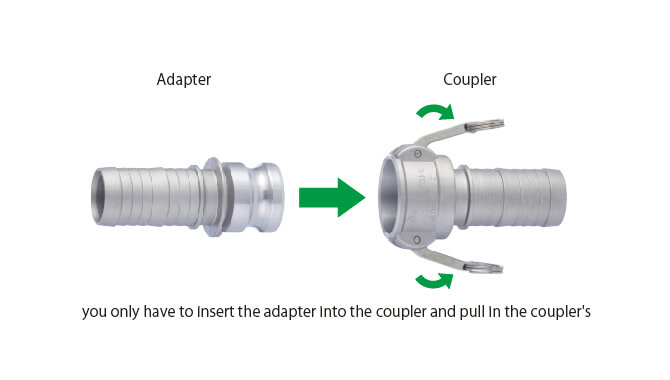

KAMLOK is a coupling composed of male (adapter) and female (coupler) that can be easily attached and detached by tightening or loosening the lever (arm). KAMLOK is available in types that connect to hoses, devices, equipment and piping materials. Also, aluminum alloy, stainless steel, bronze and polypropylene (PP) types are available to meet various applications, fluids and usage conditions.

- Q Is it okay to connect two KAMLOK made of different materials? For example, is it safe to connect an aluminum KAMLOK with a stainless steel one? Connection

-

A.

Connect with KAMLOK of the same material. Problems may occur due to electrical corrosion or wear.

- Q Does KAMLOK have couplings with different diameters to reduce the size? Model lineup

-

A.

KAMLOK does not have couplings with different diameters. There should be a method of adjusting and installing using general different-diameter bushings or the like in the thread part.

- Q Is the KAMLOK compatible with RoHS2? Laws and regulations

-

A.

All KAMLOK except for bronze models are compatible with RoHS2. Survey reports are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q I tried to insert a KAMLOK hose shank into a common suction hose, but it was difficult. Is there a good way to insert it? Connection

-

A.

There are methods such as warming the hose insertion part with warm water and applying soap water to the hose shank. Also, it is possible to change the 633-CT coupler and 633-ET adapter with a slightly narrower hose shank.

- Q Can the gasket be replaced? Is it also possible to replace the gaskets specified at the time of purchase? Gasket

-

A.

Gaskets are consumable items. They can be replaced by the customer. It is also possible to replace with the gasket specified at the time of purchase. Specify when making order.

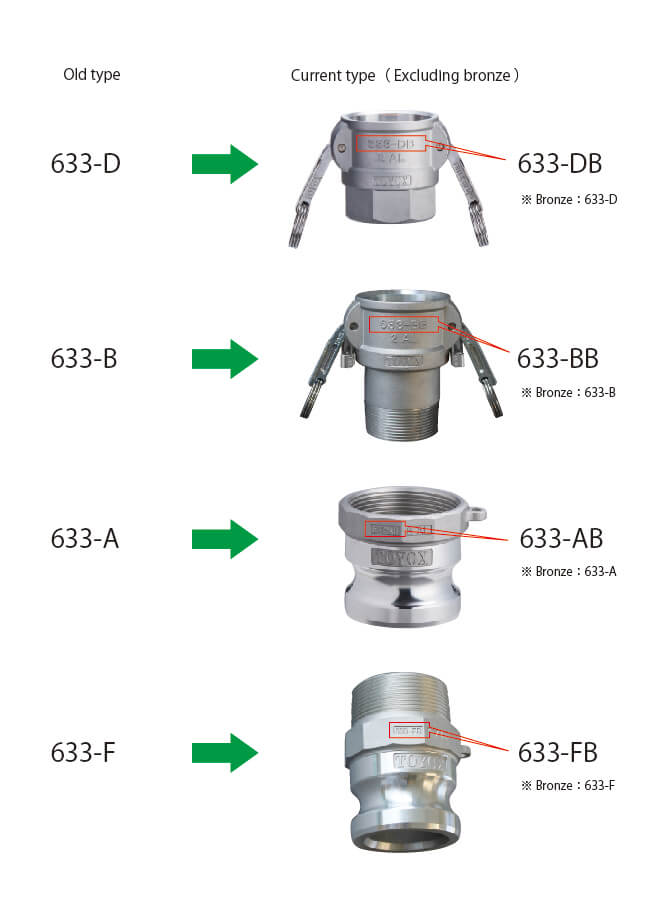

- Q The 633-A, 633-F, 633-B and 633-D engraved on the KAMLOK body don’t have products with the same part number in the catalog or website. Are they discontinued? Model lineup

-

A.

These engravings are old type. The stamps are currently the same for those made of bronze. The current product engravings and part numbers are as follows.

- Q I want to learn how to install the KAMLOK gasket. I’m trying to install a Teflon jacket gasket, but it’s tight on the side. Is it safe to push it in? Gasket

-

A.

Forcibly inserting it may cause streaks and deformation in the Teflon part, which may cause leakage. To install the gasket, immerse it in hot water at 80°C for 10-15 seconds (increasing flexibility) and firmly insert the gasket diagonally along the streaks (including the filler part). When purchasing a new product, gasket replacement can also be provided, so consult with the supplier.

- Q Is KAMLOK available in NPT thread type? Connection

-

A.

We do not carry NPT thread type. All products are PT thread type.

We provide a wide range of support from selecting ideal products for specific usage conditions to downloading certificates regarding laws and regulations, as well as downloading of materials such as catalogs.

You can download useful materials that address issues such as “leaks and disconnections”, “energy-saving measures”, and “odor and coloration.”

We use videos to introduce the benefits of using products and how to install them, which may be difficult to understand just using text and illustrations.

We have compiled frequently asked questions from customers in the “FAQ” section.

To assist you in making selections, we provide common examples of improvements for hoses and couplings through industry-based case studies.