FAQ

FAQ

FAQ

hose

View all- Q1 Can you provide product samples? Service

-

A.

In order to provide products suitable for the usage conditions, etc., we provide samples upon confirming the usage conditions.

Note that samples may not be available depending on the conditions.

- Q2 During use, hoses might bend or collapse in the middle, stopping flow or causing a change in flow rate, possibly resulting in work stoppage or loss. Is there a hose that can improve this? Function and performance

-

A.

There are various types of hoses. Hoses used in factories are roughly divided into hoses reinforced with thread and those reinforced with metal or resin coils. If the currently used hose is reinforced with thread, the hose may bend or collapse. It is possible to minimize bending and collapsing by using a hose reinforced with a metal or resin coil. These reinforced hoses are resistant to bending and collapsing and can be used for vacuum applications. In addition, there are hoses with a new structure that’s not reinforced with a metal or resin coil and is resistant against bending and collapsing.

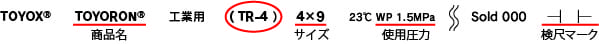

- Q3 Where on the hose should I look to find its model number? Specification

-

A.

The model number can be found in the circled part in the image below. Model numbers are marked on hoses every 1 meter. If cut into 10 cm pieces, some pieces will have no model number marking. If your piece of hose has no model number marking, please contact Toyox.

- Q4 Can gasoline be run through the TOYOFUSSO Hose? Fluid

-

A.

Do not use fuel oil in the TOYOFUSSO Hose Series. We do not produce hoses that can be used with fuel oil.

- Q5 Does the TOYOFUSSO-E Hose for antistatic use require grounding on the clamp also? How to use

-

A.

Yes. Be sure to ground or bond the hose clamp. Failure to ground may cause the hose clamp to become an isolated conductor, accumulating static electricity and leading to electrical discharge or ignition. Note that hoses with an antistatic band on the hose exterior (TOYOTOP-E Hose, TOYOTOP-E 100°C Hose, and TOYOFOODS EARTH Hose) are designed with a structure that does not generate static electricity on the surface of the hose (to a degree that static electricity could accumulate on the clamp).

coupling

View all- Q1 Are there different-diameter types of TOYOCONNECTOR for reduced size? Model lineup

-

A.

There are no different-diameter couplings for TOYOCONNECTOR. There should be a method of adjusting and installing using general different-diameter bushings or the like in the thread part.

Click here for a list of brass coupling sizes and compatible hoses

Click here for a list of stainless steel coupling sizes and compatible hoses

- Q2 Are Toyox ferrule couplings ISO-compliant? Specification

-

A.

Yes. All are ISO2852 ferrule groove compatible parts. When connecting, use a packing for ISO ferrule couplings.

- Q3 What is the difference between the male coupling and pipe thread coupling on the caulking bracket? Specification

-

A.

Male coupling is for sanitary use. It is not compatible with pipe thread.

- Q4 Do the HF, HM, HC and HNT coupling models come with gaskets? Specification

-

A.

The HC model comes with a gasket, but the other couplings do not and must be provided for separately. Toyox does not sell gaskets separately. TOYOX provides KAMLOK gaskets separately, but not other coupling packings.

- Q5 Can a TOYOCONNECTOR be attached and removed multiple times? Specification

-

A.

The TOYOCONNECTOR Series can be reused except for the all-resin type (TC3-PC). Be sure to replace the sleeve (or rubber cap depending on the product) when reusing. Also, note that it is not designed to be frequently attached or detached as in the case of disassembly cleaning.

kamlok

View all- Q1 What is the difference between the KAMLOK 633-C and 633-CT, 633-E and 633-ET? Specification

-

A.

The difference between the KAMLOK 633-C and 633-CT is the difference in the outer diameter of the shank where the hose is inserted. The 633-CT is narrower than the 633-C and is used to be inserted into hoses that do not easily expand, such as suction hoses in general. If the size does not match, fluid leakage or coupling disconnection may occur. The same applies to the 633-E and 633-ET. Use the 633-E or 633-C for our hoses.

- Q2 Can cam arms be replaced? Model lineup

-

A.

You can purchase a set containing a cam arm, pin and ring. Please let us know the material and size of your cam arm when ordering this.

- Q3 Can a 1/2″ coupler be connected to a 3/4″ adapter? Connection

-

A.

Yes, it can. The fitting areas of the 1/2″ coupler and 3/4″ adapter are the same size. Likewise, a 3/4″ coupler can be connected to a 1/2″ adapter.

- Q4 Is the KAMLOK compatible with lever type coupling made by other companies? Connection

-

A.

MIL standard lever type couplings and KAMLOK are compatible. However, the gasket specifications are different between companies. Our warranty only covers fittings and gaskets of the same manufacturer. Make sure that the size and material are the same.

- Q5 Are there any products such as lids to prevent foreign matter from entering into the KAMLOK couplings? Model lineup

-

A.

For each material, the Dust Cap 634-B is available for couplers and the Plug Cap 634-A for adapters. However, they cannot be used in applications where pressure is applied or to prevent leakage. It is only for protection from dust and foreign matter.

hose clamp

View all- Q1 Are the TOYOX hose bands compatible with RoHS2? Laws and regulations

-

A.

All hose bands are RoHS2 compatible. Certificates are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q2 Do you separately sell safety caps for safety bands? Can it be attached to the band edge of other companies’ hose bands? Part

-

A.

Safety caps for safety bands are not sold separately. In addition, you cannot attach a safety cap to the tip of another manufacturer’s hose band. In addition, do not use the product once the safety cap has been removed.

- Q3 What is the maximum tightening torque in the safety band specification table? Is there data on the optimal torque when tightening the hose? Specification

-

A.

The maximum tightening torque in the band specification table is guaranteed by the manufacturer. Exceeding it may cause damage or the band tightening function to deteriorate. There is no proper torque value. There are many hose hardnesses, wall thicknesses and coupling types. Setting up is difficult as it depends on which part of the barb to be attached. To solve such issues, we offer special couplings for tightening cap nuts called TOYOCONNECTOR that do not require torque management.

- Q4 When attaching a hose to a nipple with a clamp, where should the clamp be placed? How to use

-

A.

To securely connect the parts, fasten the clamp in the middle of the peak of the barb, above the depression. Do not fasten it immediately below the hexagonal area of the nipple. We recommend using two clamps if the hose size is greater than 1″ (25mm).