FAQ

FAQ

FAQ

hose

View all- Q1 Can sodium hydroxide (caustic soda) be run through the TOYORON Hose? Fluid

-

A.

We do not recommend doing so because that will lead to early degradation of the hose. After about a year of feeding sodium hydroxide, the hose will turn yellow and harden. After that, the hose will degrade further and become stiffer, and the inside of the hose will become brown. We therefore recommend using the ECORON or TOYOFUSSO Hose for more durability.

- Q2 Does the TOYOCAP comply with the Food Sanitation Act? Part

-

A.

Yes. It is made from polyethylene and is compliant with Japanese Food Sanitation Act Public Notice No. 201.

- Q3 Can highly concentrated ozone water be run through the TOYORON Hose? Fluid

-

A.

Yes, that is fine.

- Q4 Can ground clips replace the hose bands? How are they installed? How to use

-

A.

Ground clips are not hose bands. Be sure to use hose bands.

For attachment instructions (TOYOTOP-E100°C Hose / TOYOFOODS EARTH Hose)

- Q5 Which is the operating temperature range of the hose, inside or outside the hose? Standard

-

A.

The operating temperature range of the hose is both the fluid temperature and the atmospheric temperature.

coupling

View all- Q1 What are the differences between TOYOCONNECTORS and crimped products? Specification

-

A.

TOYOCONNECTORS adjust the length of the hose on-site Fittings can be attached by tightening a cap nut with a wrench. (Check the type of TOYOCONNECTOR and which hoses are compatible) Hose assemblies are specified by hose size, length, couplings, and are assembled by the manufacturer. (Check compatible hose and fitting types) Both are dedicated fittings for TOYOX hoses. *Crimping product fittings are not for individual sale.

- Q2 Are the TOYOX couplings compatible with RoHS2? (Other than KAMLOK) Laws and regulations

-

A.

All couplings are compatible with RoHS2 except HIT fitting (with rotation fitting female spring). Survey reports are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q3 Can you help me select the size of a barb nipple coupling for a hose? Connection

-

A.

For Toyox hoses, Toyox dedicated couplings are the best. If a genuine Toyox coupling is not provided , use a barb nipple available for purchase on the market. When selecting a barb nipple, ensure that it is appropriate for the size of the hose. It should not be used if it there is any damage or rust on the surface, and round the edges as much as possible before use.

- Q4 What is the guaranteed pressure for the TOYOCONNECTOR? Function and performance

-

A.

TOYOCONNECTOR Series is couplings dedicated for TOYOX Hoses. The warranty covers the operating pressure range of a compatible hose. However, there are temperature conditions depending on the type of TOYOCONNECTOR. Also, the material’s resistance varies depending on the fluid, so check the coupling details, chemical resistance data, etc.

- Q5 Can the TOYOCONNECTOR be used for other companies’ hoses? Connection

-

A.

TOYOCONNECTOR Series is couplings dedicated for TOYOX Hoses. Connectability with other companies’ hoses is not guaranteed. Refer to the detailed page of the corresponding TOYOCONNECTOR for compatible hoses.* Compatible hoses and sizes vary depending on the TOYOCONNECTOR part number.

kamlok

View all- Q1 What kind of coupling is KAMLOK? Specification

-

A.

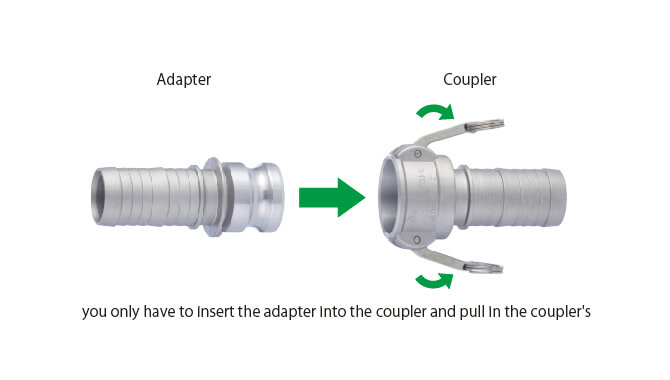

KAMLOK is a coupling composed of male (adapter) and female (coupler) that can be easily attached and detached by tightening or loosening the lever (arm). KAMLOK is available in types that connect to hoses, devices, equipment and piping materials. Also, aluminum alloy, stainless steel, bronze and polypropylene (PP) types are available to meet various applications, fluids and usage conditions.

- Q2 Is it okay to connect two KAMLOK made of different materials? For example, is it safe to connect an aluminum KAMLOK with a stainless steel one? Connection

-

A.

Connect with KAMLOK of the same material. Problems may occur due to electrical corrosion or wear.

- Q3 Does KAMLOK have couplings with different diameters to reduce the size? Model lineup

-

A.

KAMLOK does not have couplings with different diameters. There should be a method of adjusting and installing using general different-diameter bushings or the like in the thread part.

- Q4 Is the KAMLOK compatible with RoHS2? Laws and regulations

-

A.

All KAMLOK except for bronze models are compatible with RoHS2. Survey reports are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q5 I tried to insert a KAMLOK hose shank into a common suction hose, but it was difficult. Is there a good way to insert it? Connection

-

A.

There are methods such as warming the hose insertion part with warm water and applying soap water to the hose shank. Also, it is possible to change the 633-CT coupler and 633-ET adapter with a slightly narrower hose shank.

hose clamp

View all- Q1 Are the TOYOX hose bands compatible with RoHS2? Laws and regulations

-

A.

All hose bands are RoHS2 compatible. Certificates are available if necessary. Necessary survey reports can be downloaded by registering as a member. Feel free to use them as needed.

- Q2 Do you separately sell safety caps for safety bands? Can it be attached to the band edge of other companies’ hose bands? Part

-

A.

Safety caps for safety bands are not sold separately. In addition, you cannot attach a safety cap to the tip of another manufacturer’s hose band. In addition, do not use the product once the safety cap has been removed.

- Q3 What is the maximum tightening torque in the safety band specification table? Is there data on the optimal torque when tightening the hose? Specification

-

A.

The maximum tightening torque in the band specification table is guaranteed by the manufacturer. Exceeding it may cause damage or the band tightening function to deteriorate. There is no proper torque value. There are many hose hardnesses, wall thicknesses and coupling types. Setting up is difficult as it depends on which part of the barb to be attached. To solve such issues, we offer special couplings for tightening cap nuts called TOYOCONNECTOR that do not require torque management.

- Q4 When attaching a hose to a nipple with a clamp, where should the clamp be placed? How to use

-

A.

To securely connect the parts, fasten the clamp in the middle of the peak of the barb, above the depression. Do not fasten it immediately below the hexagonal area of the nipple. We recommend using two clamps if the hose size is greater than 1″ (25mm).