Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Pharmaceutical / Cosmetic / Chemical workplaces

Improvement Case

Case studiesPharmaceutical / Cosmetic / Chemical workplaces

Pharmaceutical / Cosmetic / Chemical workplaces

During tank interior steam washing, cracked hose sheath fragments may fall into the tank, causing foreign matter contamination

- Improvement by theme

-

Reduced production problems

Enhanced safety

Foreign substance contamination measures

- Fluid/Application

-

Steam

- Product name

-

TOYOSILICONE STEAM HOSE

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ Rubber hose for steam / Threaded hose nipple / Hose clamp ]

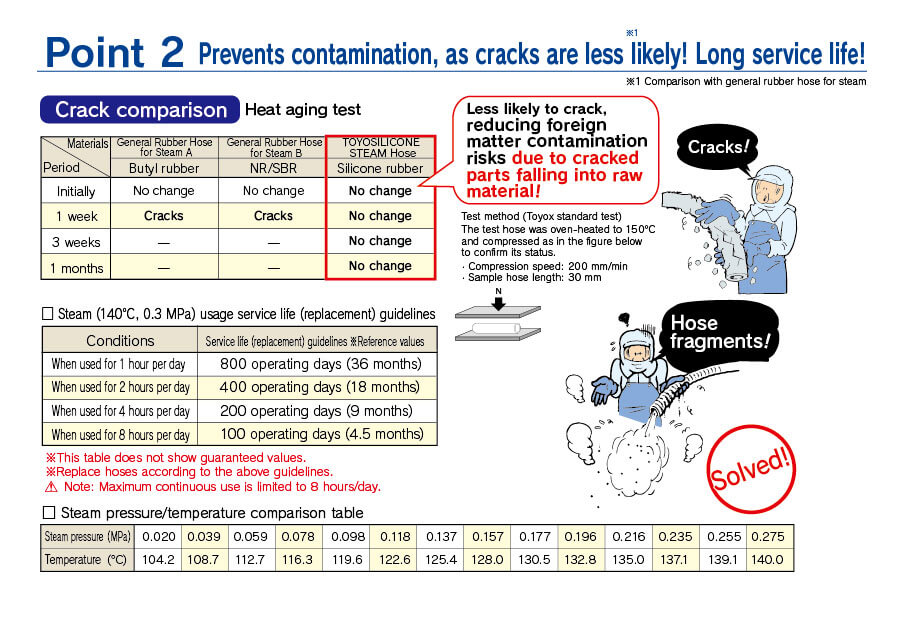

Tanks of raw material for cosmetics are regularly washed with steam, but just two to three months of use causes the steam hose sheath to crack. Measures were required for the risk of contamination with foreign matter due to small fragments of rubber from the cracked hose falling into the tank.

After[ TOYOSILICONE STEAM HOSE / TOYOCONNECTOR TC3-FS ]

Trial use of the TOYOSILICONE Steam Hose produced no cracks in the sheath over seven months, eliminating concerns over contamination with foreign matter. Use along with the dedicated TOYOCONNECTOR couplings also eliminated concerns about hose disconnection due to hose clamp fastening, enhancing safety.