Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

Plastic molding workplaces

Friction opens up holes in the hose, preventing stable supply of raw materials

- Improvement by theme

-

Reduced production problems

Improved production efficiency

Antistatic measures

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Plastic shape-retaining hose ]

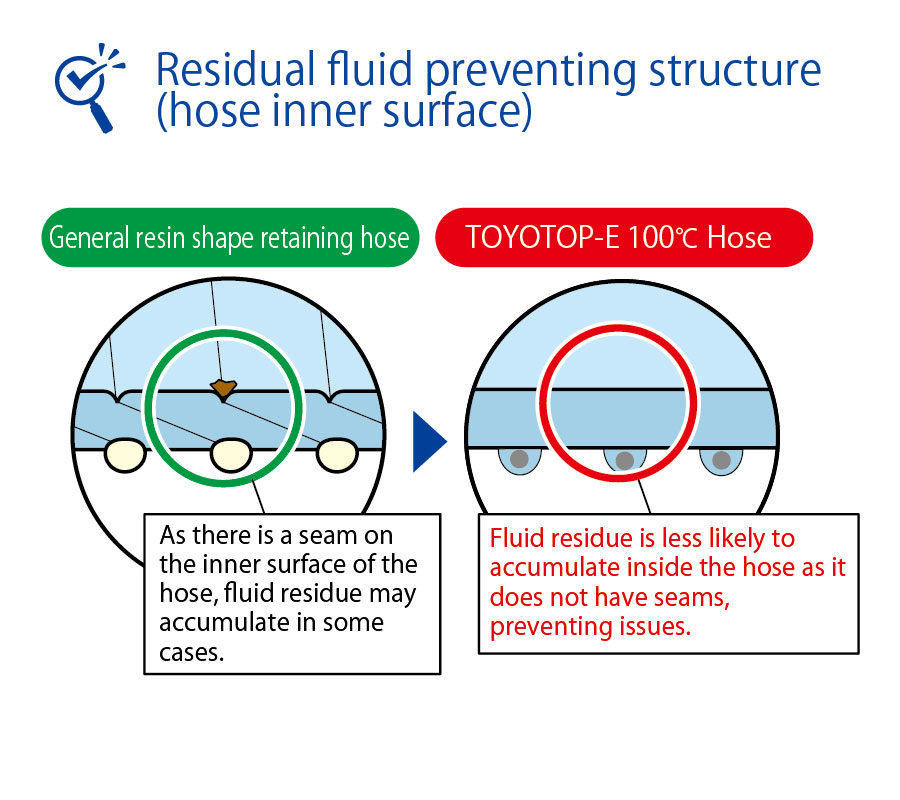

When transporting the raw material resin pellets from the dryer to the molding machine, holes can open up in the hose due to friction. While we are taking emergency measures to enable continued use, we have nevertheless been unable to supply the required volumes, molding defects have occurred, and the time set aside for emergency measures could be better utilized.

After[ TOYOTOP-E100°C HOSE ]

We tested the TOYOTOP-E 100°C hose with its heat tolerance of 100°C and resistance to friction. The hose bending parts where holes most easily appeared no longer get the holes, enabling stable transport. In addition, the antistatic function prevents uneven mixing due to static electricity, which leads to reduction in defects and other trouble due to raw material shortages, and to improved productivity.