Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

Plastic molding workplaces

Heat leads to hose collapse, preventing stable supply of raw materials

- Improvement by theme

-

Reduced production problems

Foreign substance contamination measures

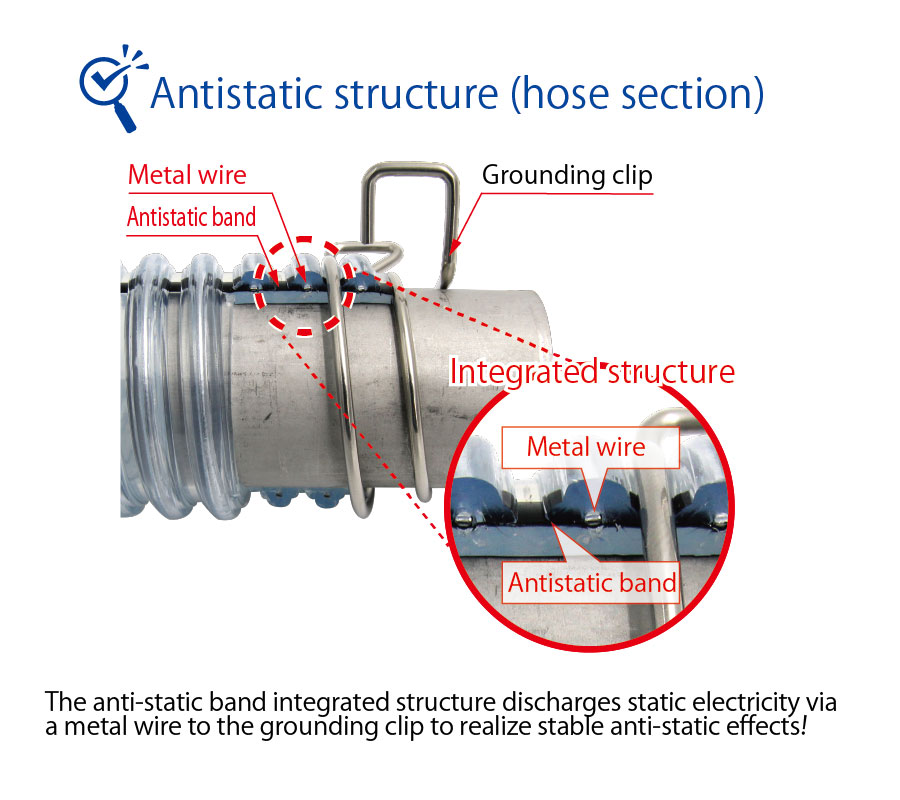

Antistatic measures

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Plastic shape-retaining hose ]

Hoses used for transfer of PET resin at drying temperatures of 80°C to 100°C collapsed due to the heat, preventing the stable supply of raw materials and leading to frequent mold defects. As well, static electricity was generated from the powder transfer, adhering the raw materials to the hose interior so that the materials mixed during changeover and contaminated the product with foreign matter, which also required countermeasures.

After[ TOYOTOP-E100°C HOSE ]

Replacement with the TOYOTOP-E-100°C Hose, with heat-resistant and antistatic functions, prevented hose collapse and enabled a stable supply of raw materials. Without the influence of static electricity, the adherence of raw material was no longer a problem, reducing product defects free of concern about foreign matter contaminating the product.