Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

Reduced coloration of the hose inner layer for improved work efficiency

- Improvement by theme

-

Foreign substance contamination measures

Improved production efficiency

Coloring and odor countermeasures

- Fluid/Application

-

Food and beverage

- Product name

-

TOYOFUSSO SOFT−S HOSE

- Product type

-

Industrial hoses

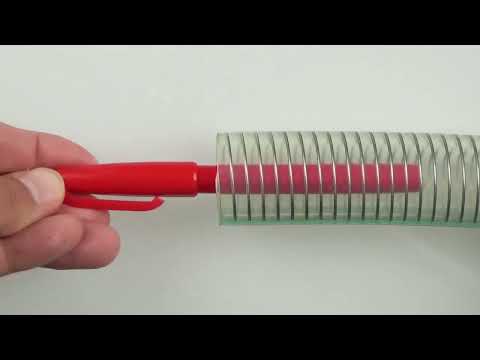

Before[ PVC spring hose ]

A PVC hose with coils was used for fluids from high to low viscosity. There was severe hose interior coloration after fluid transport and cleaning, leading to hose replacement within six months. Measures were considered for reducing the hose replacement rate and preventing foreign matter intrusion due to fluid remaining within the hose.

After[ TOYOFUSSO SOFT−S HOSE ]

A TOYOFUSSO Soft-S-50φ hose was used for monitoring. With high transparency, the interior was found to be easily visible so that dirt was easily confirmed; the hose could also be used in good condition without coloration. Switching on other lines is also being considered.