Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

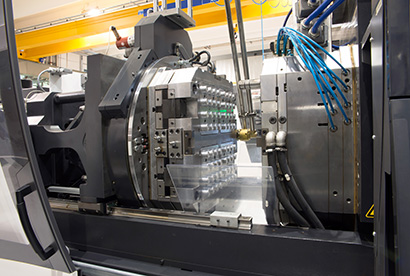

Plastic molding workplaces

Eliminating leakage problems, and making piping work easier and faster

- Improvement by theme

-

Reduced time spent on work

Reduced production problems

Cost reduction

- Fluid/Application

-

Water (non-potable)

- Product name

-

TOYOCONNECTOR TC3-B

/

TOYOCONNECTOR TC3-S

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ SUPER TOYORON Hose / Threaded hose nipple / Hose clamp ]

Toyox’s SUPER TOYORON hose and barb fittings with hose clamp fastening were used as piping for supplying cooling water to factory machinery. However, water began to leak from the connections between the hose and the couplings. In addition to suddenly having to deal with production stoppages and to clean up the water leakage, the manufacturer also had to prevent the equipment from being exposed to the water, which would have caused a malfunction.

After[ SUPER TOYORON HOSE / TOYOCONNECTOR TC3-B / TOYOCONNECTOR TC3-S ]

After watching Toyox’s pressure resistance comparison video between barb fittings with hose clamp fastening and TOYOCONNECTOR couplings, the manufacturer decided to adopt TOYOCONNECTOR couplings for their superior safety. Introducing the TOYOCONNECTOR couplings eliminated water leakages and other problems, opening the door to stable operations and reliable production. The manufacturer was also very happy with the reduction in assembly time and the greatly improved operability, and plans to switch over piping in other locations in the future.