Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

Productivity improved by eliminating hose bending and collapse and water leaks from the coupling

- Improvement by theme

-

Reduced production problems

- Fluid/Application

- Product name

-

HYBRID TOYOSILICONE HOSE

/

TOYOCONNECTOR TC6-FS

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ PVC braided hose / Ferrule hose nipple / Hose clamp ]

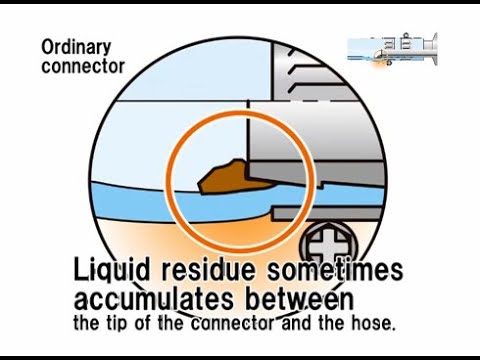

A sake company was using a non-phthalate food grade hose with barb hose clamp fastenings for product transfer to the blending tank and transport of 80°C hot water. However, the high temperature caused hose bending and collapse as well as leaks from the couplings, reducing production efficiency and requiring a change.

After[ HYBRID TOYOSILICONE HOSE / TOYOCONNECTOR TC6-FS ]

The customer viewed videos comparing bending in TOYOSILICONE Hoses and pressure resistance and safety by coupling type, deciding to adopt a HYBRID TOYOSILICONE Hose and TOYOCONNECTOR. Hose replacement frequency went down and leaks disappeared, enabling stable production. The same products were likewise to be introduced sequentially to other lines.