Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

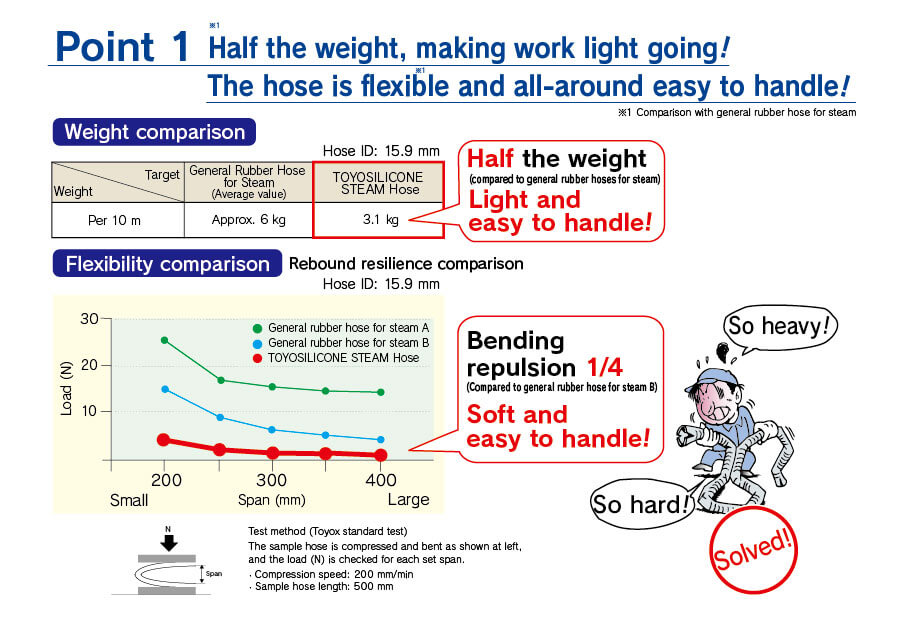

The steam hose is heavy, so the cleaning work is tough. In addition, foreign matter intrusion due to inner hose deterioration is a concern

- Improvement by theme

-

Improved workability

Enhanced safety

Foreign substance contamination measures

- Fluid/Application

-

Steam

- Product name

-

TOYOSILICONE STEAM HOSE

/

TOYOCONNECTOR TC3-FS

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ Rubber hose for steam / Ferrule hose nipple / Hose clamp ]

To steam clean the cheese adhering to pots and machines, we used a steam hose (made of rubber) with a ferrule barb hose band fastening.

This steam hose is heavy and stiff, making it difficult to use. Moreover, after about one year of use, rubber fragments appear due to inner hose deterioration. Foreign matter intrusion due to the hose fragments is a concern, and we concluded that some countermeasure needed to be done.

After[ TOYOSILICONE STEAM HOSE / TOYOCONNECTOR TC3-FS ]

When we switched to light and soft TOYOSILICONE Steam, the cleaning became much easier.

In addition, a half-year has now elapsed since starting use, and there has been absolutely no change to the hoses, enabling long-term use and lowering the possibility of foreign matter intrusion due to deterioration, eliminating our concerns.

Furthermore, we switched to TOYOCONNECTOR for leak and disconnection prevention with hose couplings that can also be tightened with a cap nut, for a safety countermeasure that eliminates concerns about hose disconnection when using the hose band.