Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

Frequent hose replacement with hose assemblies in use means high costs and long lead times for crimped products, requiring countermeasures

- Improvement by theme

-

Reuse

Cost reduction

- Fluid/Application

- Product name

-

TOYOSILICONE-S HOSE

/

TOYOCONNECTOR TC3-FS

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ Silicone hose with crimped coupling ]

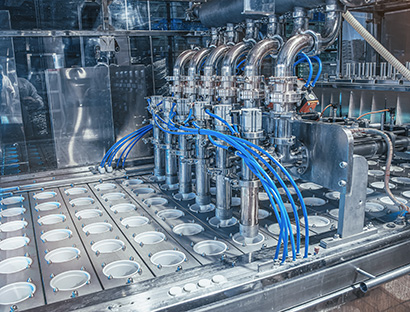

During the flavoring filling process, a food-grade silicone hose and crimping couplings were used, but the frequent suction and pressure feed in the process meant regular hose replacement; costs mounted for crimping couplings which could not be reused.

After[ TOYOSILICONE-S HOSE / TOYOCONNECTOR TC3-FS ]

Switched from hose assemblies to cap-nut type TOYOCONNECTOR FERRULE, which can be mounted on site and used repeatedly with only individual parts replaced. The hose alone is regularly replaced, with the couplings available for repeated use, sharply reducing costs. Because our own workers can mount the components, lead time is no longer an issue and rapid handling is possible, a great success all around.