Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

Liquid accumulation between barb fittings and hoses is a concern due to dairy components in flavorings

- Improvement by theme

-

Reduced production problems

Foreign substance contamination measures

Reduced product loss

- Fluid/Application

-

Animal/vegetable oil

Heat-resistant

Food and beverage

- Product name

-

TOYORING-F HOSE

/

TOYOCONNECTOR TC3-F

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ PVC braided hose / Threaded hose nipple / Hose clamp ]

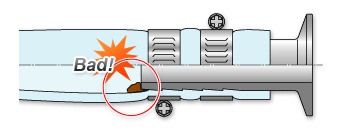

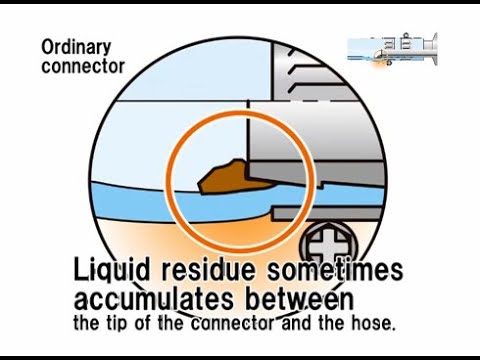

Newly introduced production of flavorings containing large amounts of dairy components requires more stringent bacterial inspections, due to the nature of the product. The hoses are currently connected with barb fittings for hose clamp fastening, but the bumps may lead to liquid accumulation, requiring countermeasures.

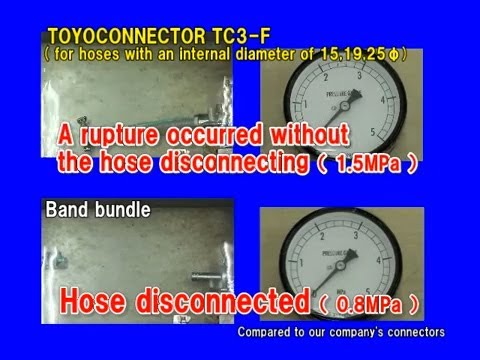

After[ TOYORING-F HOSE / TOYOCONNECTOR TC3-F ]

To examine the use of the food grade hose TOYORING-F and cap nut fastened couplings which can be mounted on site to prevent liquid accumulation (TOYOCONNECTOR FERRULE), we conducted (1) ATP inspections, (2) bacterial inspections, and (3) allergen inspections, the results of all of which met in-house criteria. The products were immediately adopted for all production lines in the plant. They have resulted in production with peace of mind.