Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

Removing and reattaching 200 hoses every day for cleaning is a lot of work!

- Improvement by theme

-

Improved workability

Reduced maintenance

- Fluid/Application

-

Food and beverage

- Product name

-

TOYOSILICONE HOSE

/

FERRULE Coupling (Hose Assemblies) HF

/

TOYOCONNECTOR TC3-FS

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ TOYOSILICONE Hose / Ferrule hose nipple / Hose clamp ]

TOYOSILICONE Hoses were used for conveying salad dressing and the hoses were initially cut to about 30 centimeters and fastened with clamps. But there were between 100 to 200 hoses in the plant, and they all had to be removed, washed and reattached every day. There were two problems:

(1) It took too much time

(2) The edges of the clamps were causing damage to the hoses, which had to be replaced.

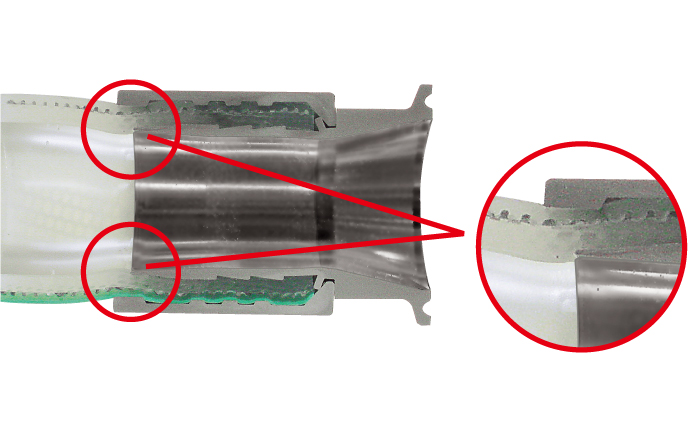

After[ TOYOSILICONE HOSE / FERRULE Coupling (Hose Assemblies) HF / TOYOCONNECTOR TC3-FS ]

By switching to the TOYOSILICONE Hose assemblies that do not allow liquids to accumulate easily and do not require disassembly for cleaning, and to the TOYOCONNECTOR that can be adjusted and replaced at the worksite, the efficiency of cleaning and attaching/detaching has been greatly improved.