Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Pharmaceutical / Cosmetic / Chemical workplaces

Improvement Case

Case studiesPharmaceutical / Cosmetic / Chemical workplaces

Pharmaceutical / Cosmetic / Chemical workplaces

Static electricity causes powder to stick to the hose, reducing production efficiency

- Improvement by theme

-

Enhanced safety

Improved production efficiency

Antistatic measures

- Fluid/Application

-

Powders

- Product name

-

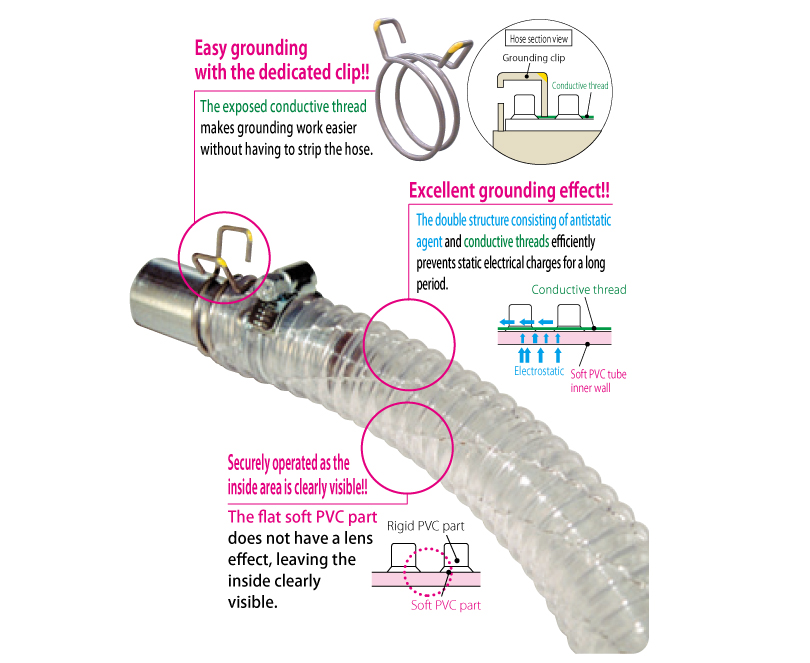

TOYOTOP-E HOSE

- Product type

-

Industrial hoses

Before[ Grounding hose ]

In a factory that produces agricultural chemicals, hoses would cause a small static shock when workers touched them, even though the hoses were grounded. The hose was used to convey powder materials, which would stick inside the hose. This loss of efficiency was a major problem for the producer.

After[ TOYOTOP-E HOSE ]

Switched to antistatic TOYOTOP-E Hose. Charging was suppressed, which provided safety, eliminated clogging of raw materials and improved productivity. The TOYOTOP-E Hose has an antistatic effect due to the double effect of blended antistatic agent and conductive threaded. It also enables easy grounding.