Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Pharmaceutical / Cosmetic / Chemical workplaces

Improvement Case

Case studiesPharmaceutical / Cosmetic / Chemical workplaces

Pharmaceutical / Cosmetic / Chemical workplaces

Hose keeps coming off, causing a major loss causing a major loss of liquid concenterate

- Improvement by theme

-

Reduced production problems

Reduced product loss

- Fluid/Application

-

Chemicals and cosmetics

- Product name

-

TOYOSILICONE HOSE

/

FERRULE Coupling (Hose Assemblies) HF

- Product type

-

Industrial hoses

/

Industrial couplings

Before[ PVC braided hose / Ferrule hose nipple / Hose tightened with two hose clamps ]

A PVC hose was fastened with barb and two clamps in a process for filling undiluted liquid soap. But the nipple would disconnect, causing the soap to spill out. This was a major problem in terms of product loss as well as requiring extra labor to clean up the floors, which became a slippery hazard when the soap spilled.

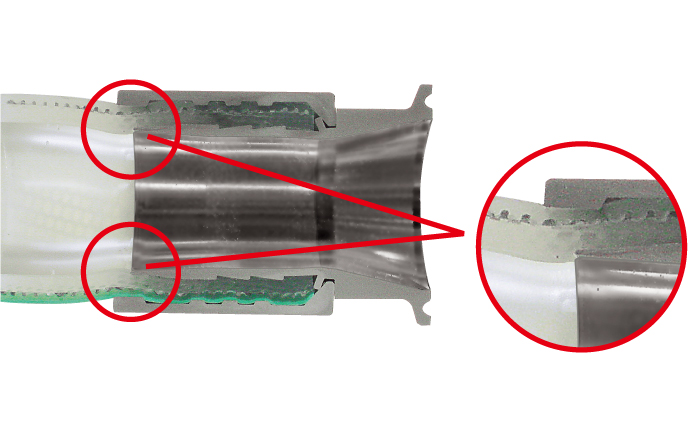

After[ TOYOSILICONE HOSE / FERRULE Coupling (Hose Assemblies) HF ]

In order to prevent the coupling from disconnecting, it was changed to TOYOSILICONE Hose assemblies. The crimped coupling eliminated concerns for disconnection and reduced losses. In addition, the coupling was changed to FERRULE, providing easy connection and improved workability.