Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

Plastic molding workplaces

Raising the mold temperature causes liquid to leak onto the product, resulting in product defects

- Improvement by theme

-

Reduced production problems

Reduced product loss

- Fluid/Application

-

Water (non-potable)

Mineral oil

- Product name

-

TOYOSILICONE HOSE

- Product type

-

Industrial hoses

/

Industrial couplings

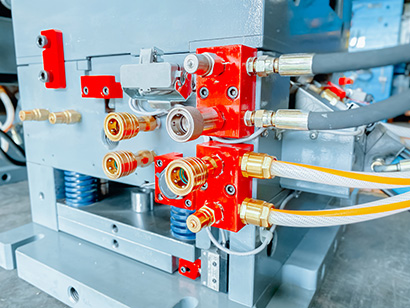

Before[ Rubber hose / Threaded hose nipple / Hose clamp ]

To reduce the defect rate, a customer raised their die temperature from between 60 and 80°C to between 80 and 95°C. This temperature increase however, caused the rubber hose circulating the hot water for regulating die temperature to become brittle sooner than expected. This resulted in cracks, and hot water leaking onto the product again, causing more product loss.

After[ TOYOSILICONE HOSE / TOYOCONNECTOR TC3-SS ]

The heat-resistant TOYOSILICONE Hose prevents disconnections due to brittleness. This eliminated the secondary loss of our customer’s products. Problem solved!