Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Plastic molding workplaces

Improvement Case

Case studiesPlastic molding workplaces

Plastic molding workplaces

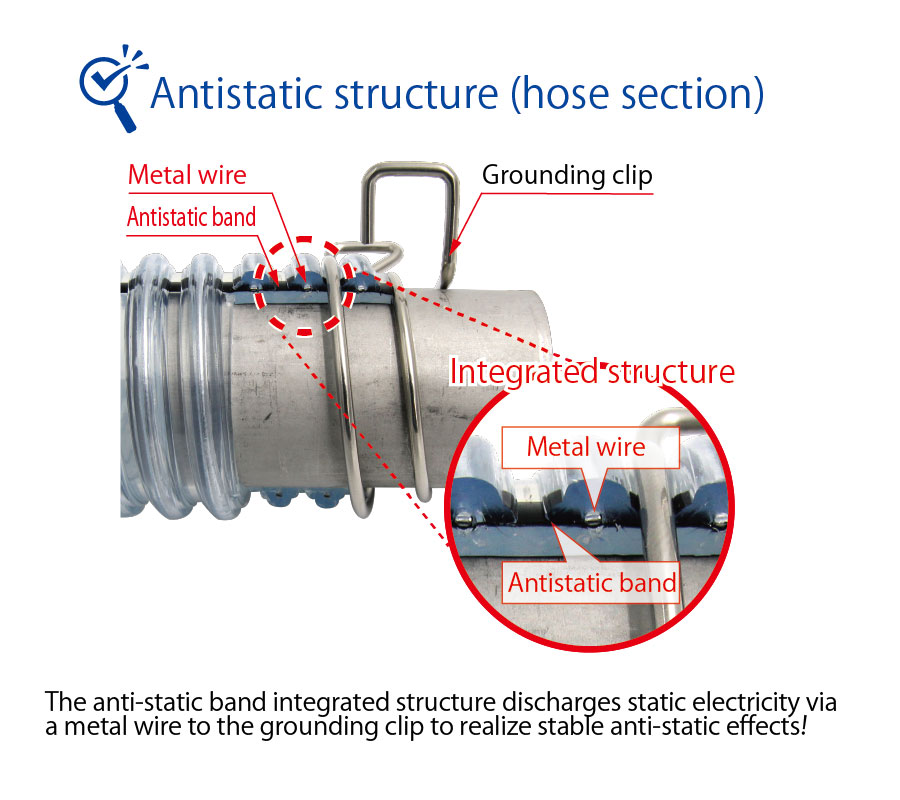

The improved anti-static design shortens cleaning times for greater work efficiency

- Improvement by theme

-

Reduced time spent on work

Reduced production problems

Antistatic measures

- Fluid/Application

-

Plastics powder and granular materials

- Product name

-

TOYOTOP-E100°C HOSE

- Product type

-

Industrial hoses

Before[ Suction hose ]

A suction hose was used to transport plastic pellets to molding machinery.

Static electricity was generated during operation, which caused pellets to block the hose, disrupting production. Because the hose was opaque, it was difficult to tell where the blockage occurred. Locating the blockage took time, which made production less efficient.

After[ TOYOTOP-E100°C HOSE ]

We began using the TOYOTOP-E 100°C Hose, a highly transparent hose with an antistatic design. A dedicated clip is used for easy grounding, preventing pellets from building up in the hose. The hose is soft, making it easy to connect to dryers and hoppers and enabling quick cleaning. These qualities have earned it rave reviews from our customers.