Search by application

Search by method of connection with device

Select by device/piping connection type

-

Search Products

-

Industrial Hoses

-

Search by application

-

Search by usage conditions

-

Select from chemical resistance information

-

Search by model

-

-

Industrial Couplings

-

Search by method of connection with device

-

Search by method of connection with hose

-

Search by usage conditions

-

Select from compatible couplings for your hose

-

Select from chemical resistance information

-

-

KAMLOK

-

Search by product category

-

Select by device/piping connection type

-

Search by usage conditions

-

Select from chemical resistance information

-

-

Gardening/watering products

-

Simplified piping system

-

-

Support and Downloads

- Inquire Now

- Hose Adviser Pro

Phone:+81-765-52-3131

- TOP

- ・

- Toyox Support

- ・

- Case studies

- ・

- Food and beverage workplaces

Improvement Case

Case studiesFood and beverage workplaces

Food and beverage workplaces

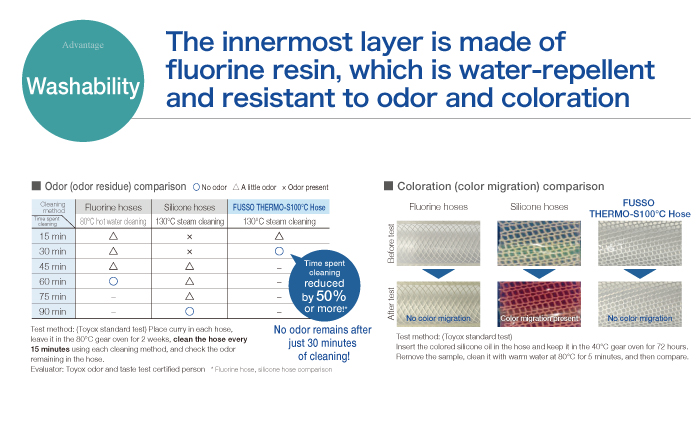

Less color migration (coloration) in the hose and reduced cleaning time

- Improvement by theme

-

Foreign substance contamination measures

Improved production efficiency

Coloring and odor countermeasures

- Fluid/Application

-

Heat-resistant

Food and beverage

- Product name

-

FUSSOTHERMO-S100°C HOSE

- Product type

-

Industrial hoses

Before[ Silicone hose ]

A silicone hose was used to flow red perilla extract at 90°C during the beverage production process. Color tended to remain in the hose, and the hose cleaning process was time-consuming. In addition, the hoses were replaced with new hoses once a year to prevent foreign substance contamination.

After[ FUSSOTHERMO-S100°C HOSE ]

We tried out the FUSSOTHERMO-S100°C Hose, which is heat resistant to 100°C and its innermost layer is made of fluorine resin. No coloring or surface stickiness, and little odor residue after washing. In addition, production engineering workers have evaluated the product as less likely to bend and easier to handle than silicone hoses.